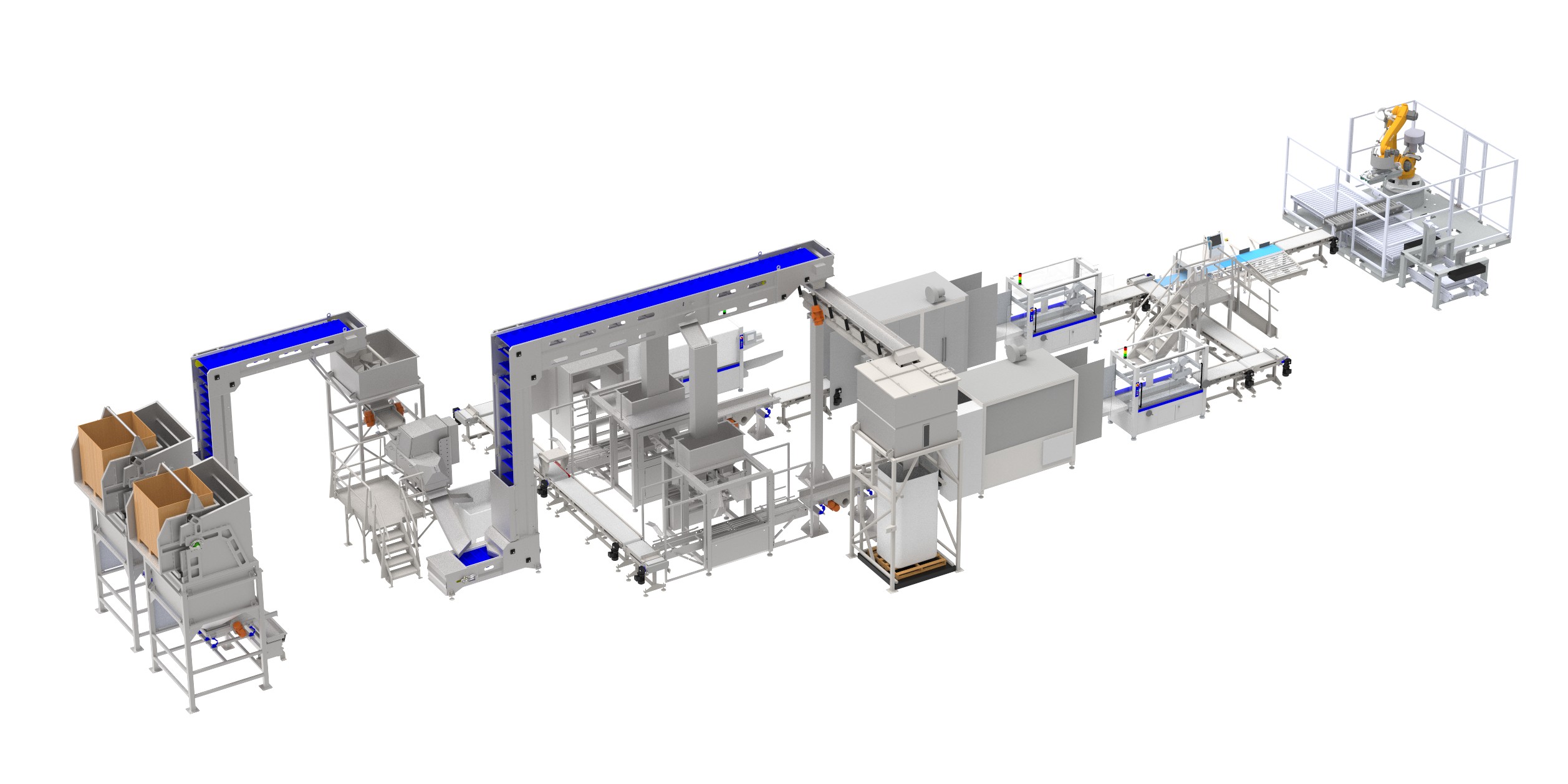

dUAL CASE FILL AND PACKAGING SYSTEM

GWI’s Dual Case Fill and Pack System is a fully integrated end-of-line packaging solution that combines case erecting, product filling, case closing/sealing, and robotic palletizing in a single automated workflow. Designed to streamline secondary packaging operations, the system accepts empty corrugated cases, erects and positions them, fills them with product, securely seals the cases, and transfers finished boxes to robotic palletizers for stacking. Built for high throughput and reliable performance, this integrated solution improves operational efficiency, reduces manual labor, and supports consistent packaging quality.

Features:

- Automatic case erecting and forming

- Precise product fill and load control

- Secure case closing and sealing

- Robotic or automated palletizing

- Integration-ready conveyors and controls

Competitive Advantages:

- Single-source, fully integrated system: Combining case erecting, filling, sealing, and palletizing for synchronized, efficient operation.

- In-house engineered and manufactured: Ensuring precise integration, consistent performance, and customized line layouts.

- Reduced labor and downtime: Achieved through automated case handling and streamlined end-of-line workflows.

- Scalable, automation-ready design: Integrates seamlessly with upstream processing and adapts to changing production demands.