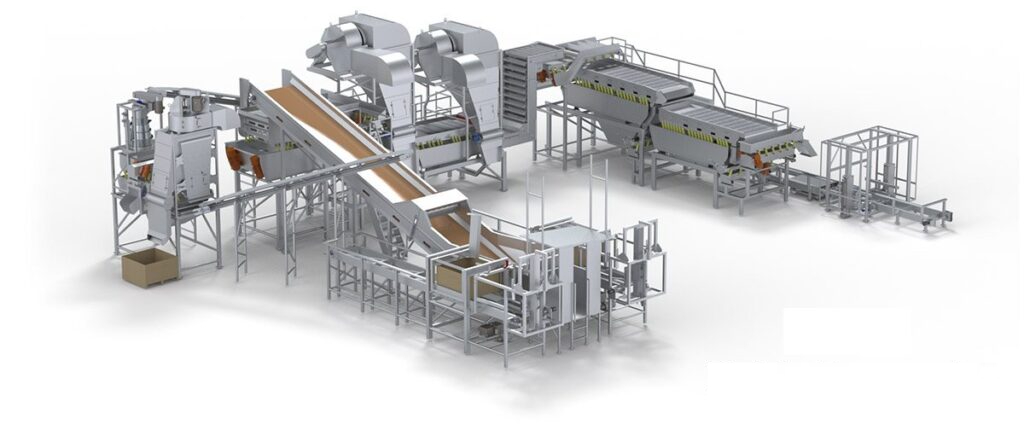

COMPLETE RAISIN WASHING AND PACKING SYSTEM

GWI’s raisin washing and packing systems provide the highest quality and efficiency in cleaning, washing, rinsing, and de-watering your product. Depending on your products moisture

Home » Raisin Processing

GWI stands out for its comprehensive raisin processing machinery and equipment that offer solutions for every stage of raisin production, from initial cleaning to final packaging. By integrating advanced technology, ensuring sanitary design, and providing customizable solutions, GWI supports raisin processors in achieving high efficiency, quality, and productivity. By incorporating advanced technology, sanitary design, and customizable solutions, we ensure our equipment meets the diverse needs of the raisin processing industry, making GWI a strong contender in the market.

GWI stands out for its comprehensive, customizable, and high-tech raisin processing solutions.

Fields marked with an * are required

For decades GWI has strived to become a front-runner in the food processing industry and has been successful in accomplishing this feat in many areas. We dedicate ourselves on providing our customers with superior Raisin Processing Line Machinery with exceptional client service. High quality finish and attention to detail of our products are extremely important to us. Look no further than GWI to accomplish your wants and needs. Our equipment processes provide high production return and minimal operation cost. GWI’s Raisin Processing Lines are available in a variety of specifications and configurations to accommodate your product capacities from 2 to 30 tons per hour. GWI raisin lines cover the following:

GWI’s raisin washing and packing systems provide the highest quality and efficiency in cleaning, washing, rinsing, and de-watering your product. Depending on your products moisture

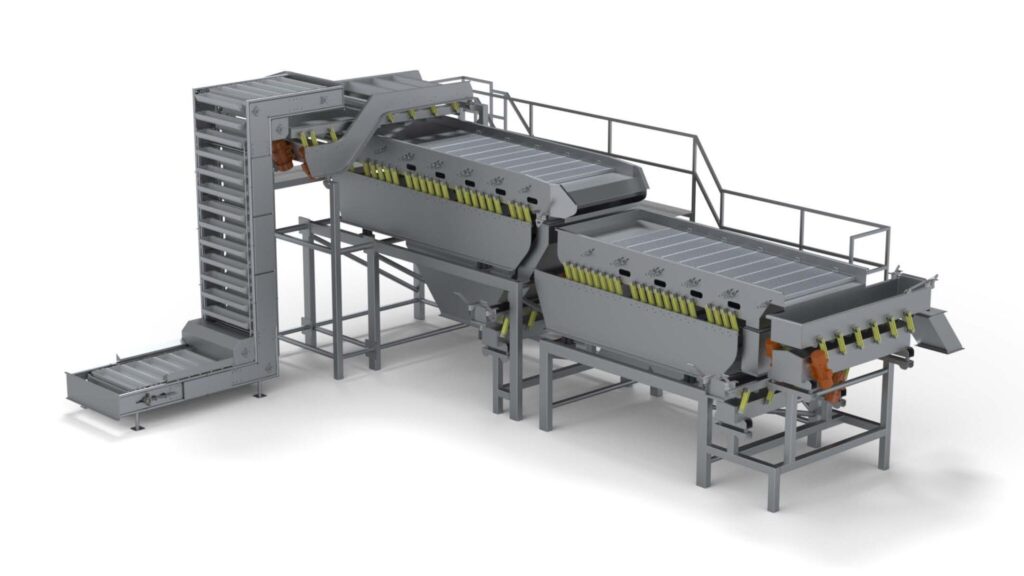

GWI’s raisin grading systems provide the highest quality and efficiency in separating, cleaning, and sizing of your raisins. Simultaneously, our grading systems will remove stems, dirt, and

Expertise and Experience

With extensive experience in designing and manufacturing food processing equipment, GWI provides innovative solutions tailored to your needs.

Customer-Centric Solutions

Our team works closely with clients to deliver customized raisin processing solutions that enhance operational efficiency and productivity.

Quality Assurance

Every system is rigorously tested to meet the highest standards of quality and performance before leaving our factory.

Contact our team of experts to find the best raisin processing system for your application. We offer comprehensive support from design to installation and maintenance.

Installation and Training

GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

Maintenance and Support

Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

Customization Consultation

Expert consultation to design and customize processing lines tailored to specific requirements.

Contact our team of experts to find the best nut processing system for your application. We offer comprehensive support from design to installation and maintenance.

Ghazarian Welding Inc. 2903 E. Annadale Ave. Fresno, CA 93725

Tel: (559) 2331210

Fax: (559) 233-6963