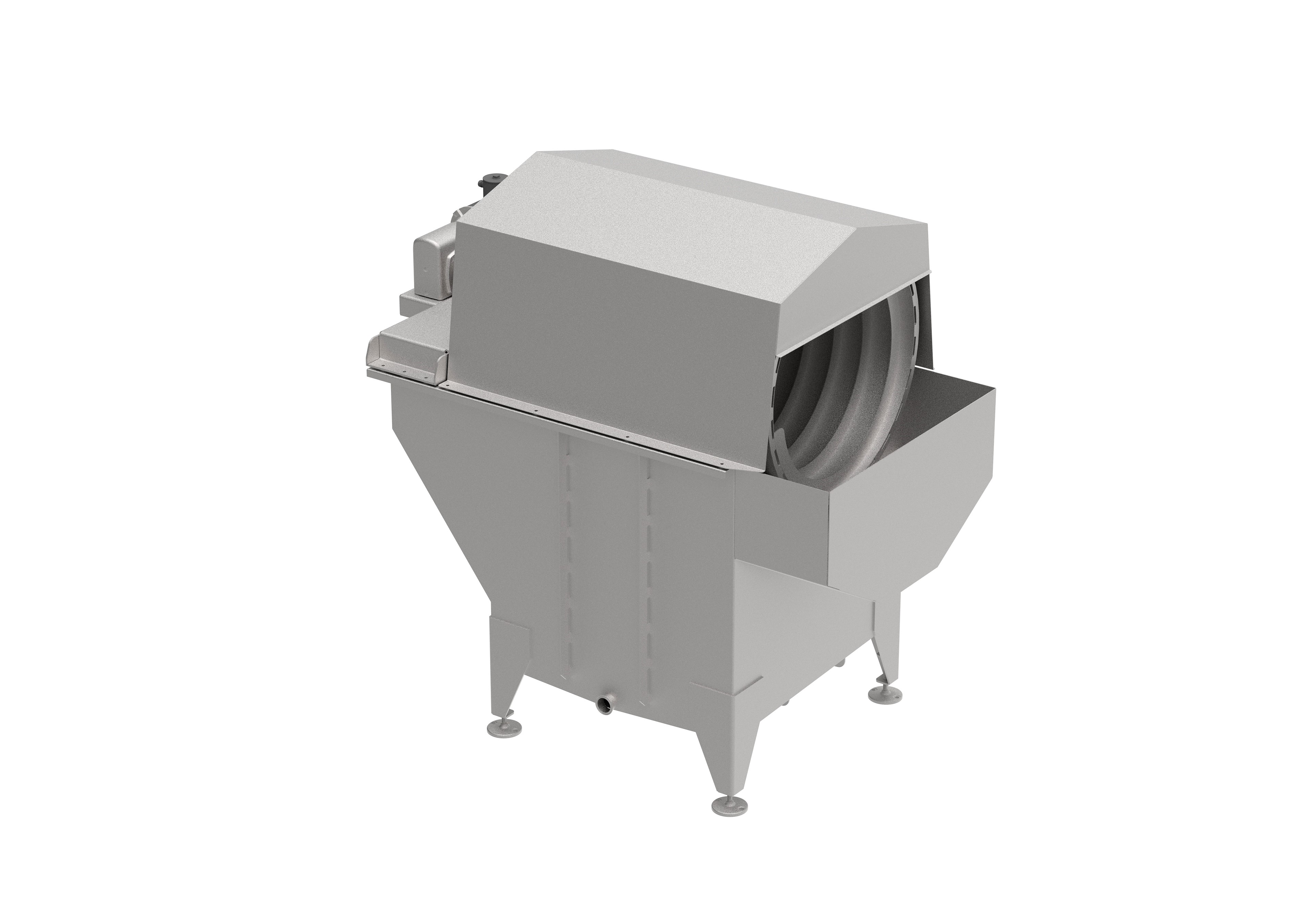

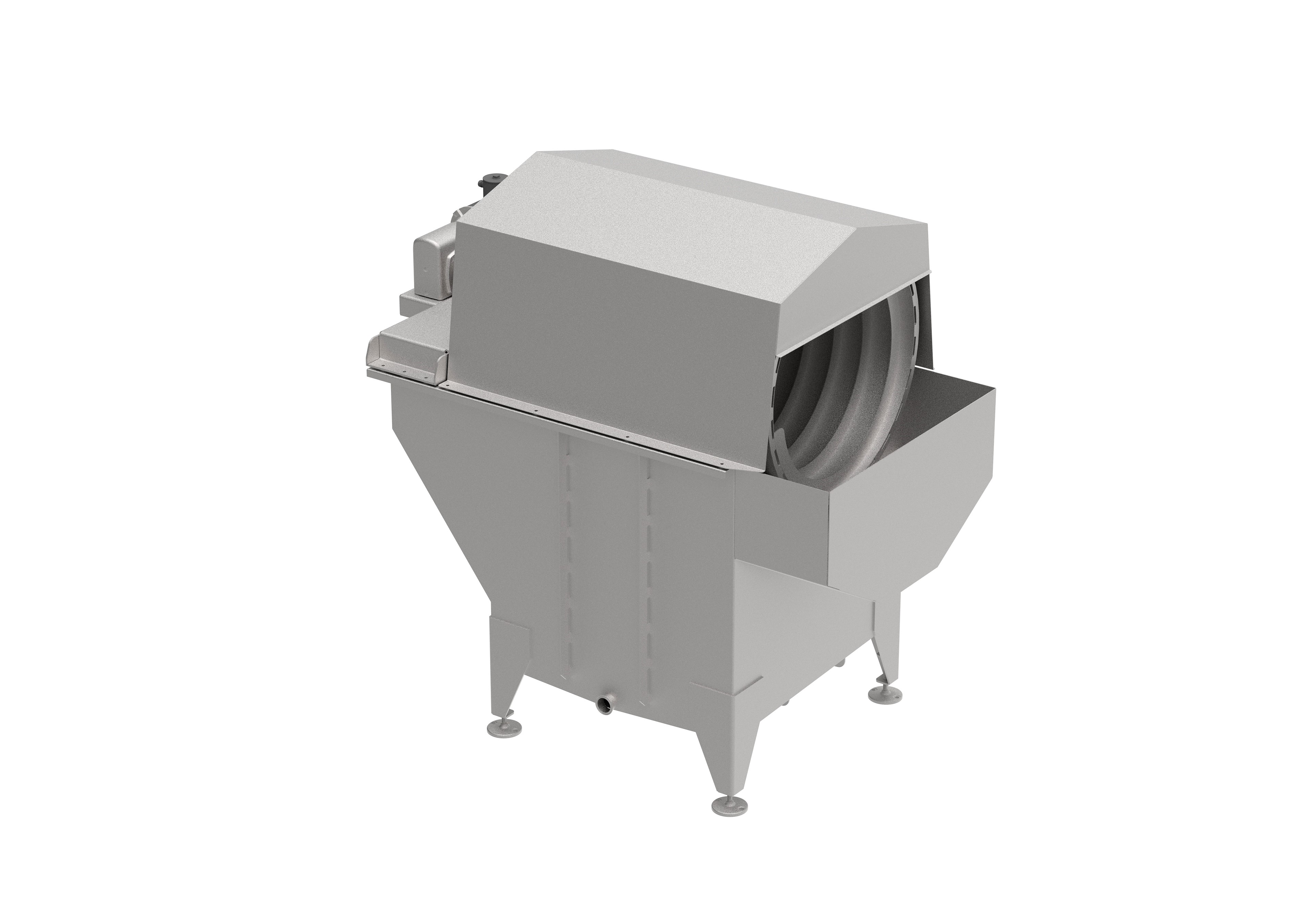

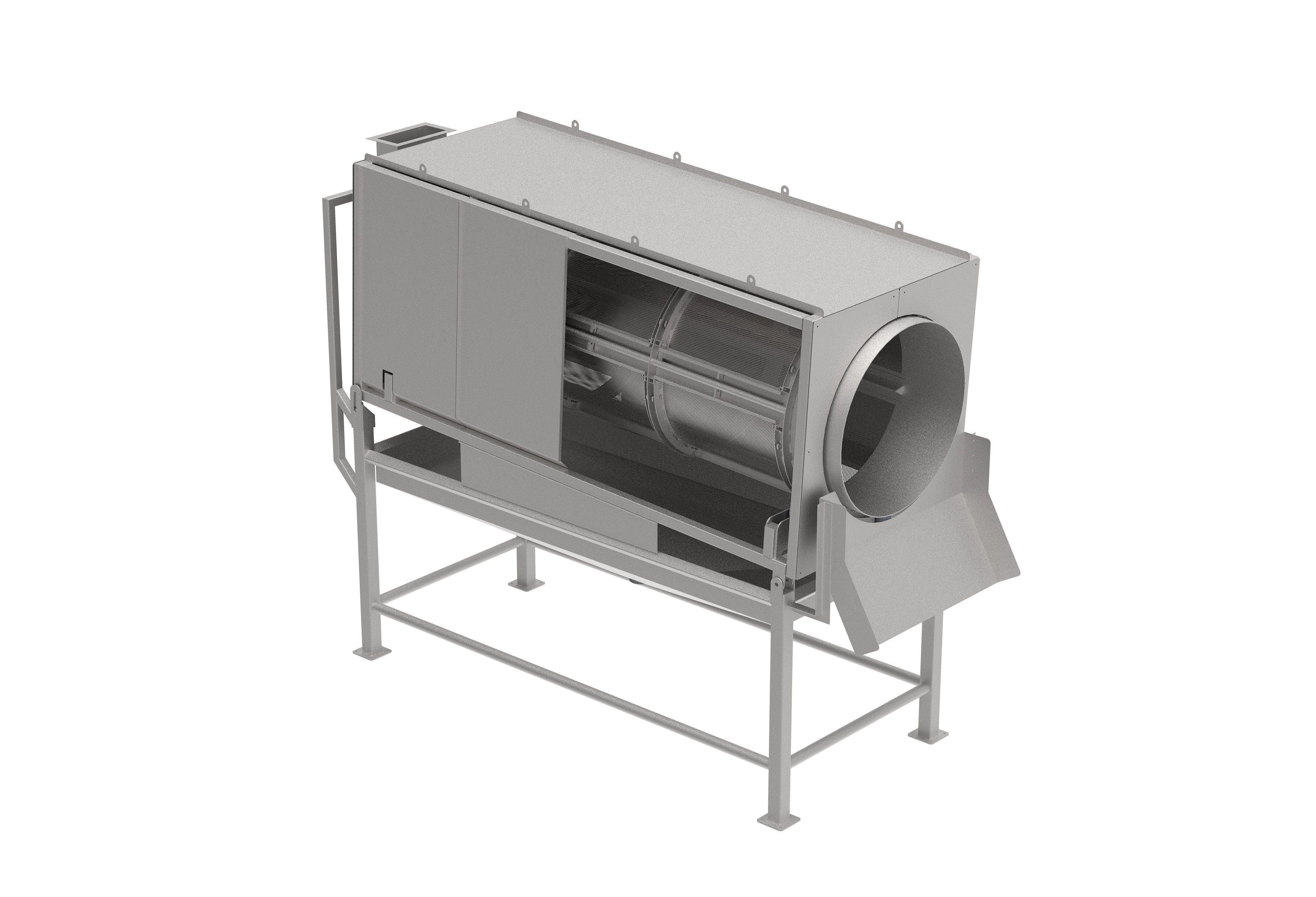

WATER LIQUID RECLAIM REEL

GWI’s Water, Liquid Reclaim Reel provides an advanced, efficient solution for water reclamation and recycling within the food processing industry. Designed to meet sanitary standards,

Home » TUMBLERS, COATING, & RINSING REELS

GWI offers a range of cutting-edge rotary separators, washing systems, and flavoring tumblers specifically designed to meet the needs of the food processing industry. Our equipment is built for precision, hygiene, and efficiency, ensuring that your food processing operations run smoothly while maintaining product quality. From custom designs to turnkey solutions, GWI is your trusted partner in optimizing bulk material handling and processing.

GWI’s rotary separators are designed to efficiently separate and sort bulk materials in food processing plants. These machines are essential for maintaining consistent product quality by removing unwanted debris and ensuring even distribution of materials before further processing.

GWI’s Water, Liquid Reclaim Reel provides an advanced, efficient solution for water reclamation and recycling within the food processing industry. Designed to meet sanitary standards,

GWI’s Rinsing De-Watering Tumblers are designed for high-capacity, efficient performance in the food processing industry. These industrial rinsing and de-watering tumblers deliver sanitary, precise, and

GWI’s Flavor Coating Tumblers are engineered to deliver precise, efficient seasoning and coating for the food processing industry. These industrial flavor coating equipment systems ensure

Interested in learning more about how GWI’s rotary separators, washing systems, and flavoring tumblers can benefit your food processing operations? Contact us today to discuss your needs and discover how our high-efficiency, custom solutions can help you achieve your production goals.

Contact our team of experts to find the best nut processing system for your application. We offer comprehensive support from design to installation and maintenance.

Ghazarian Welding Inc. 2903 E. Annadale Ave. Fresno, CA 93725

Tel: (559) 2331210

Fax: (559) 233-6963