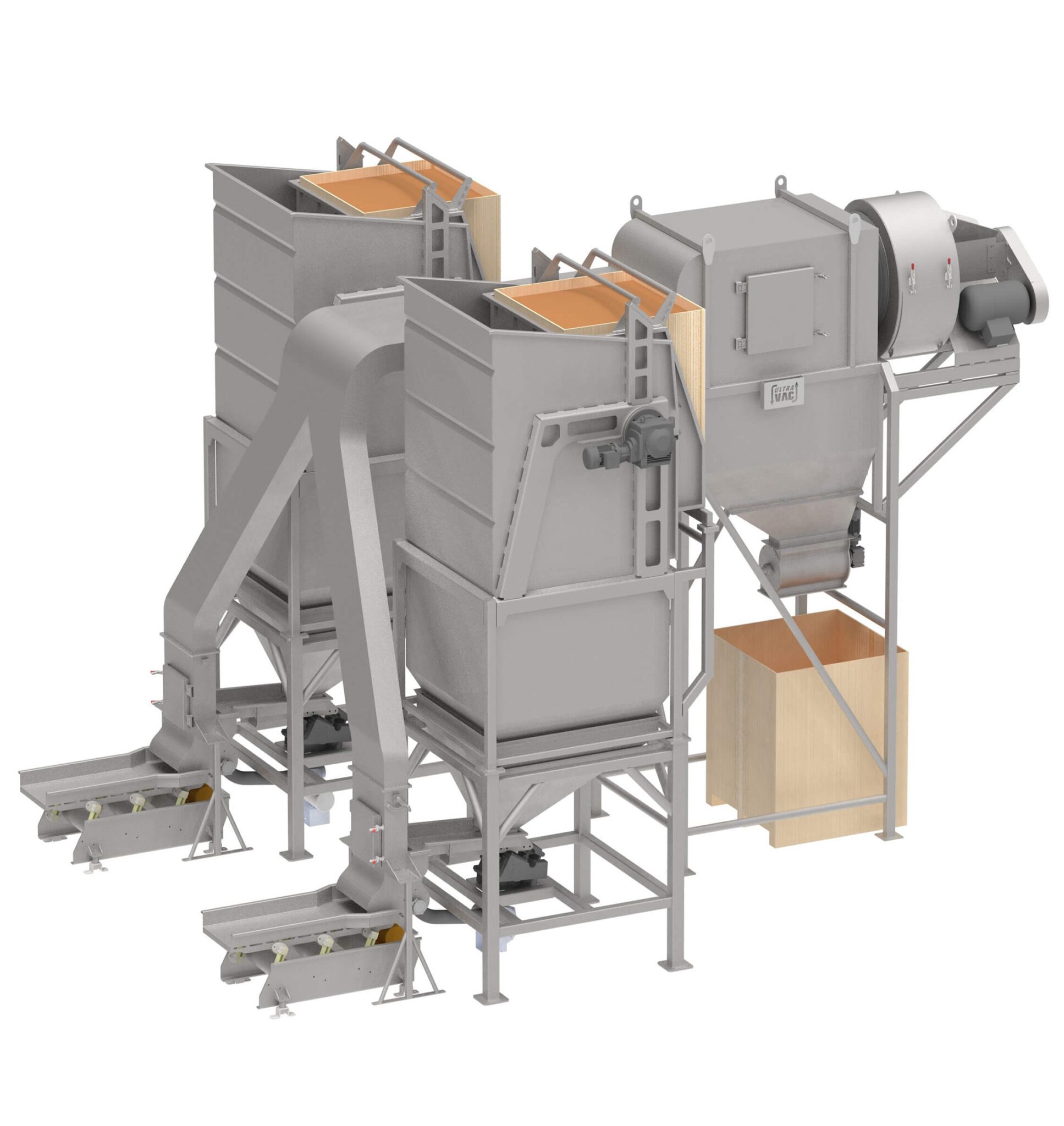

UVS AIR-ASPIRATION SYSTEM

GWI’s UVS air aspiration systems are engineered and designed to provide continuous high-performance separation of unwanted materials from accepted materials with throughputs of up to 60,000 lbs. per hour. The UVS can separate debris from products such as dried fruits, vegetables, leafy products, peppers, cauliflower, broccoli, tomatoes, walnuts, almonds, pistachios, and much more. GWI’s UVS systems are highly efficient user friendly and low maintenance design.

UVS SYSTEMS INCLUDE:

- Separation of almond “doubles” from whole product

- Separation on splits and chips of cashews from whole good product

- Shell separation after cracking (pistachios, walnuts, macadamia, and almonds)

- Stems, sticks, fines and unwanted materials from fruits, nuts, vegetables, and much more

- Wine grape seed separation from undesirable materials

- Pre-cleans a variety of products prior to optical sorting

GWI’s industrial air aspiration systems are essential for grain cleaning processes, effectively separating light impurities from heavier grains. These systems ensure that your grain handling operations are efficient and that the final product is of the highest quality.

Features Include:

- Efficient Separation: Removes chaff, dust, and other light impurities from grains.

- High Capacity: Designed to handle large volumes of grain with consistent performance.

- Durable Construction: Built to withstand the demands of industrial grain processing.

Contact Us

Interested in learning more about how GWI’s air aspiration systems can benefit your operation? Contact us today to discuss your needs and find out how our high-efficiency, customizable solutions can help you achieve your production goals.

Support and Services

- Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

- Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

- Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.