Industrial De-Clumping Solutions for Dried Commodities

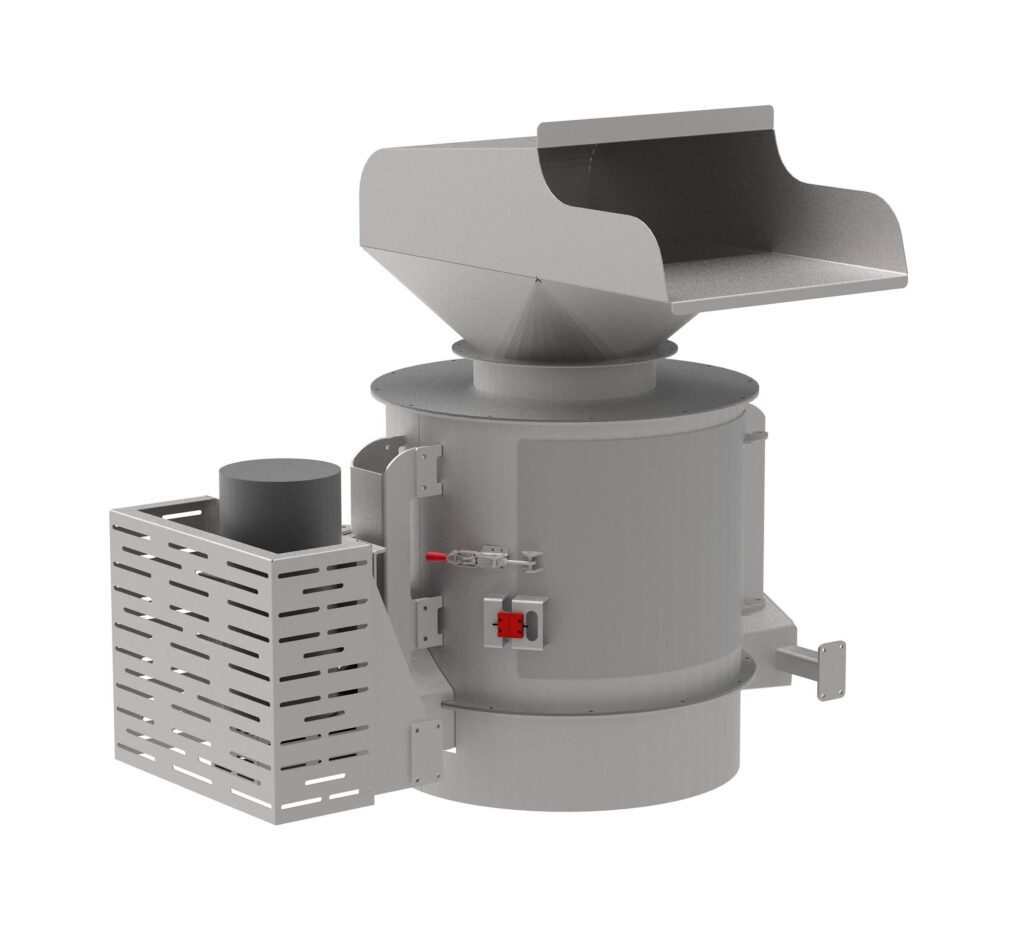

GWI’s de-clumpers are engineered to ensure smooth, efficient processing by eliminating clumps in bulk materials. Whether you’re handling powdered food products or other bulk materials, our de-clumpers offer the high efficiency and reliability you need to maintain product quality and streamline your production processes.

In the food processing industry, maintaining consistent material flow is critical. GWI’s industrial de-clumpers are designed to break up clumps in bulk materials, ensuring smooth, uninterrupted processing. These machines are essential for operations that handle powders, grains, and other materials prone to clumping.

Key Features:

- Robust Design: Built to withstand the demands of industrial food processing environments.

- Consistent Performance: Effectively reduces clumps, ensuring uniform material flow.

- Versatile Applications: Suitable for a wide range of food products, including powders, granules, and more.

Contact Us

Interested in learning more about how GWI’s de-clumpers can benefit your food processing operations? Contact us today to discuss your needs and discover how our efficient, customizable solutions can help you achieve your production goals.

Support and Services

- Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

- Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

- Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.