Bucket-Type

GWI’s Bucket-Type Elevators provide reliable, high-capacity solutions for food processing applications, ensuring the safe and efficient transport of materials. Designed with sanitary standards in mind,

Home » GWI Elevators for Food Processing

GWI’s elevators are engineered for reliability and efficiency, making them essential for bulk material handling in the food processing industry. From custom-built designs to turnkey solutions, our elevators ensure seamless integration into your production lines while enhancing productivity and maintaining product quality.

GWI’s industrial elevators are designed to handle the rigorous demands of the food processing industry. Built with durability and precision in mind, these elevators transport bulk materials with minimal downtime, ensuring your production line operates at maximum efficiency.

GWI’s Bucket-Type Elevators provide reliable, high-capacity solutions for food processing applications, ensuring the safe and efficient transport of materials. Designed with sanitary standards in mind,

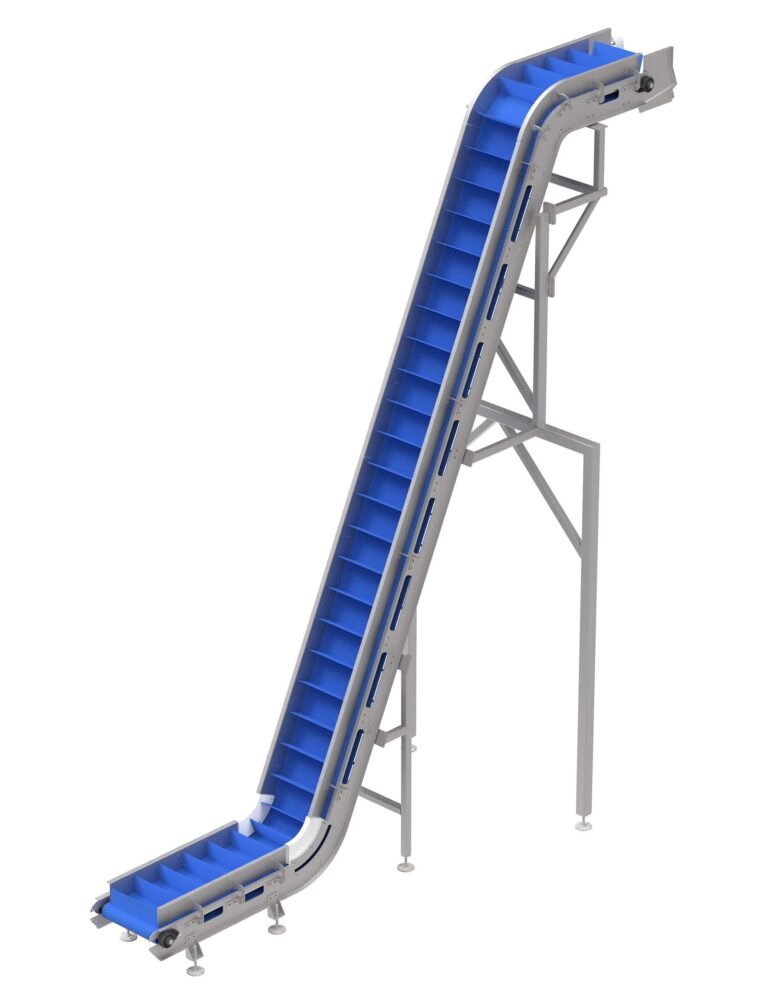

GWI’s Incline Belt-Type Elevators are designed to provide efficient and sanitary solutions for food processing and other industrial applications. Built for durability and precision, these

GWI’s U-Trough-Type Conveyors are designed to meet the specific demands of food processing and other industrial applications, providing efficient and sanitary handling for bulk materials.

Interested in learning more about how GWI’s elevators can improve your food processing operations? Contact us today to discuss your needs and find out how our high-efficiency, custom elevator solutions can help you achieve your production goals.

Contact our team of experts to find the best nut processing system for your application. We offer comprehensive support from design to installation and maintenance.

Ghazarian Welding Inc. 2903 E. Annadale Ave. Fresno, CA 93725

Tel: (559) 2331210

Fax: (559) 233-6963