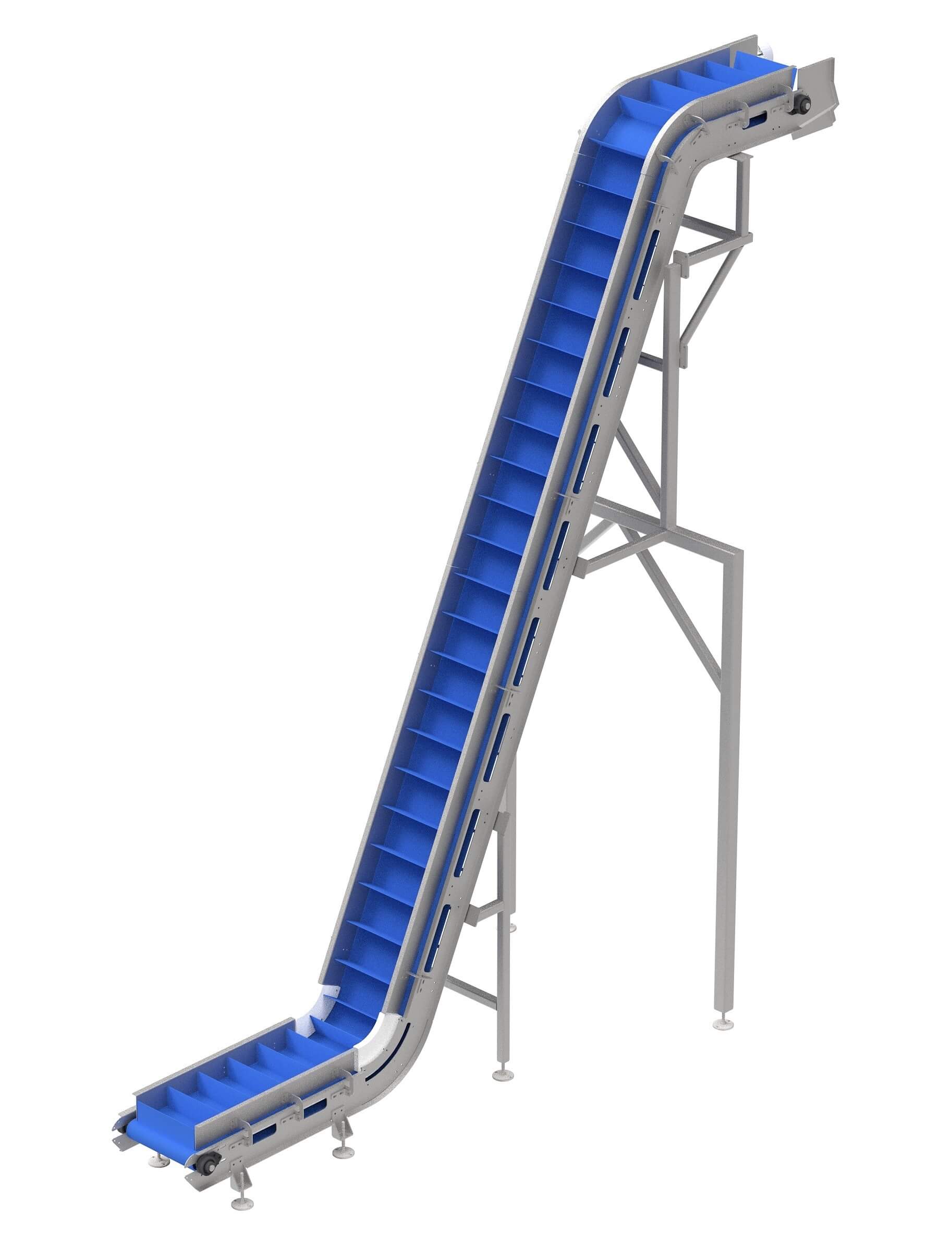

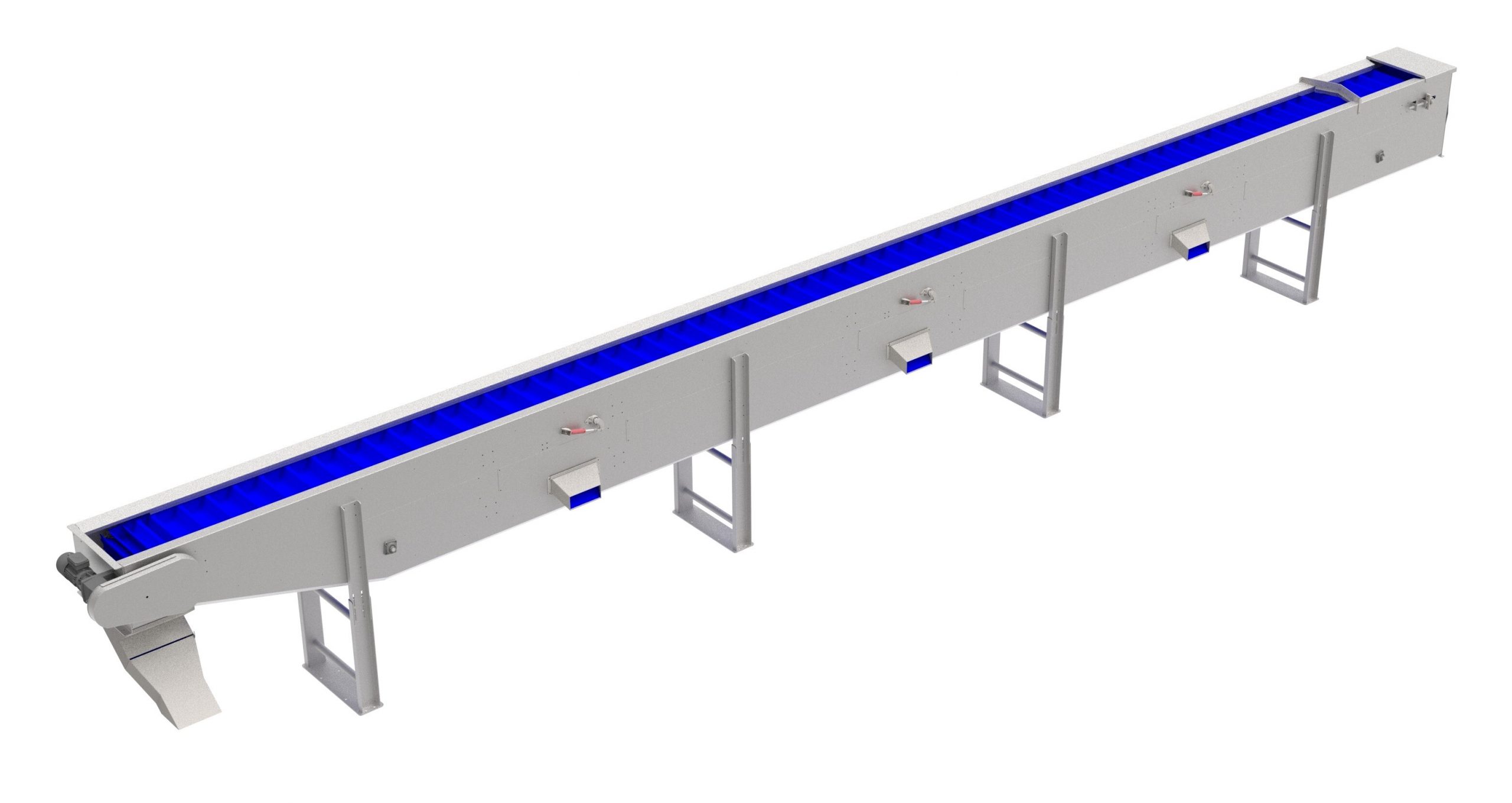

INCLINE PROFILE

GWI’s custom incline profile conveyors are designed to meet the specific needs of food processing and bulk material handling industries. Our conveyors ensure the efficient

Home » BELT, CHAIN, BUCKET, ROLLER, & SCREW TYPE CONVEYORS

Explore GWI’s custom conveyor systems with high-efficiency, sanitary, and automated conveyor solutions tailored for the food industry and material handling.

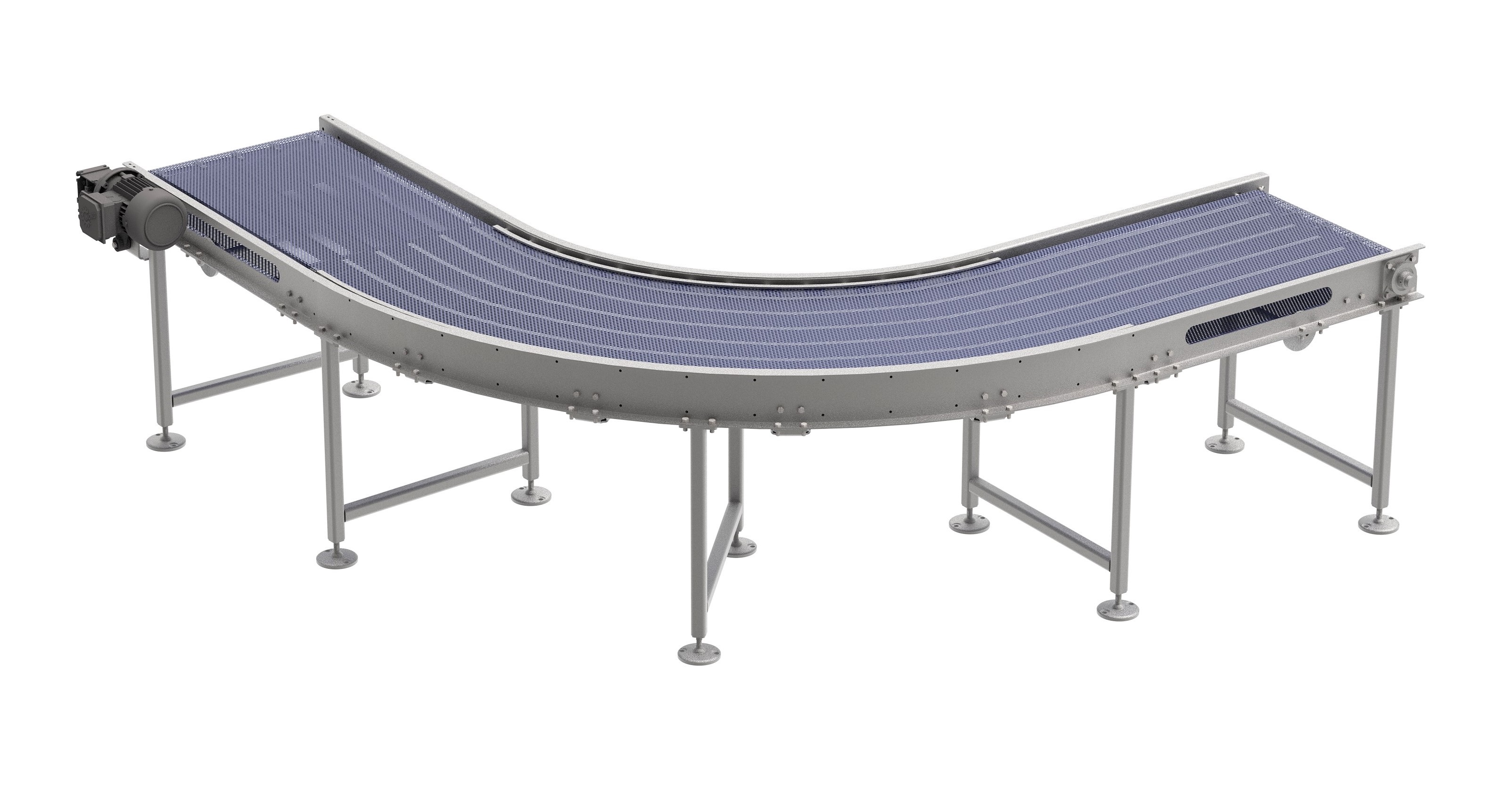

GWI offers a comprehensive range of conveyor systems specifically designed for the food processing industry. Our conveyors are engineered to enhance efficiency, maintain product quality, and meet stringent hygiene standards. Whether you need custom solutions or turnkey systems, GWI provides the expertise and equipment to optimize your production line.

Increasing throughput and capacity requirements, shorter processing times, and rising operational costs are driving production and distribution companies to consider automated conveyor systems. GWI has built a strong reputation for designing, building, installing, including servicing conveyor systems to help companies move their products and materials more efficiently through our industrial conveyor automation solutions. We manufacture a wide variety of options for industrial conveyor systems that are fast and efficient to meet and exceed expectations in transporting loads and materials within an area.

GWI’s industrial conveyor systems are built to handle a variety of materials, from raw ingredients to finished products. Our conveyors are designed to withstand the rigorous demands of food processing environments, ensuring reliable performance day after day.

GWI’s custom incline profile conveyors are designed to meet the specific needs of food processing and bulk material handling industries. Our conveyors ensure the efficient

Our advanced bulk metering systems for moving materials offer precision and durability, ensuring seamless flow management across industries. Designed for high-accuracy bulk material handling, our

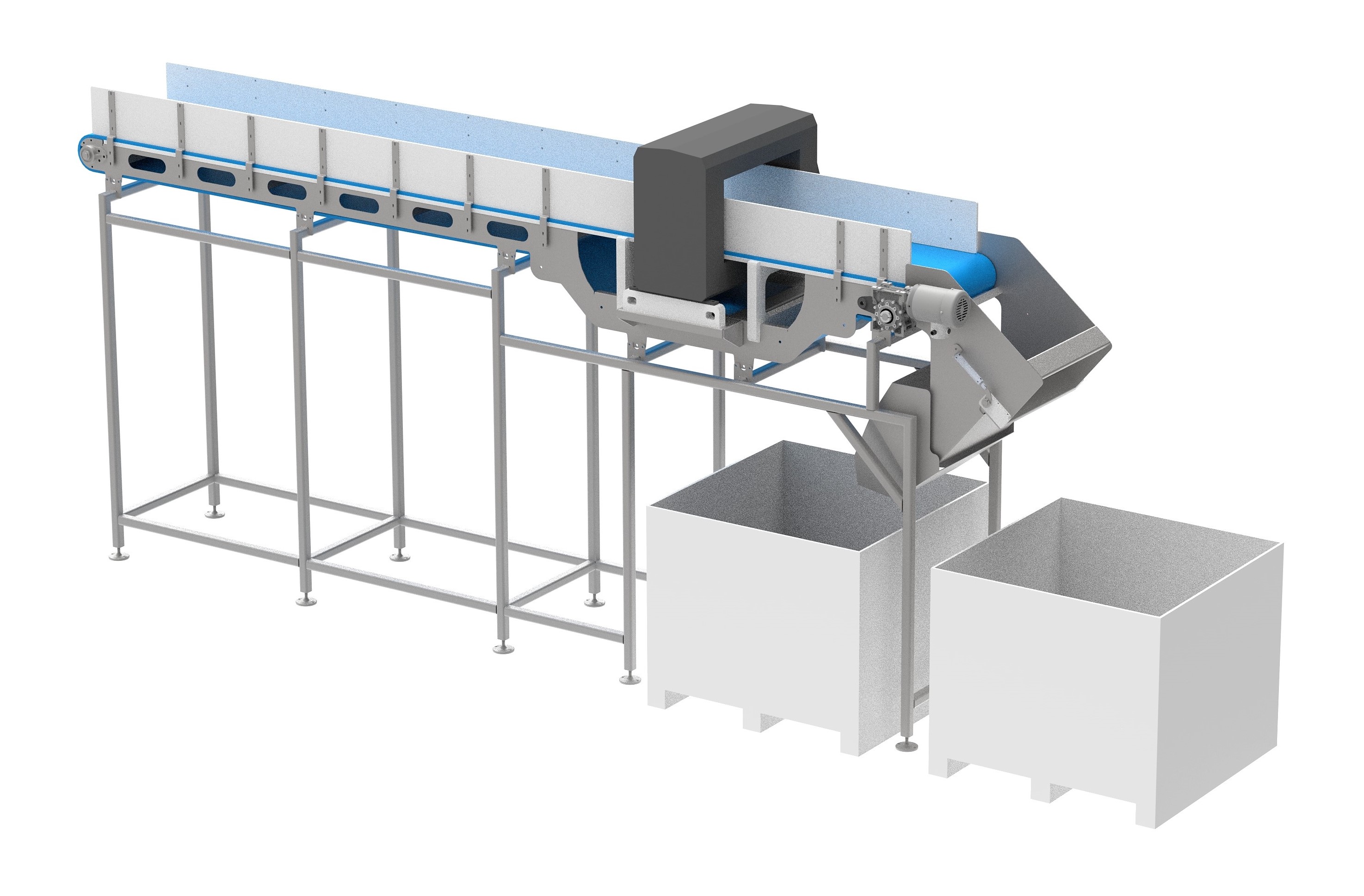

Looking to buy high-sensitivity metal detecting conveyors for enhanced quality control in food processing or material handling industries? Our industrial metal detecting conveyors for sale

Discover our automated accumulation turntables for production lines, designed to increase production efficiency while reducing labor costs. Our adjustable height rotary accumulation tables for warehouses

Discover our high-performance nose transition belts for material handling systems, designed to enhance efficiency and reduce downtime in your operations. Our adjustable nose transition belts

Explore our high-capacity bucket distribution conveyors for manufacturing, engineered to enhance efficiency in material handling. Our automated bucket distribution conveyors for warehouses provide seamless integration

GWI’s V-trough conveyors are engineered for efficient bulk material handling across food processing and industrial sectors, ensuring smooth, automated material flow with minimal maintenance. These

Our screw conveyors or auger conveyors are mechanical devices used for transporting bulk materials from one location to another. They consist of a rotating helical

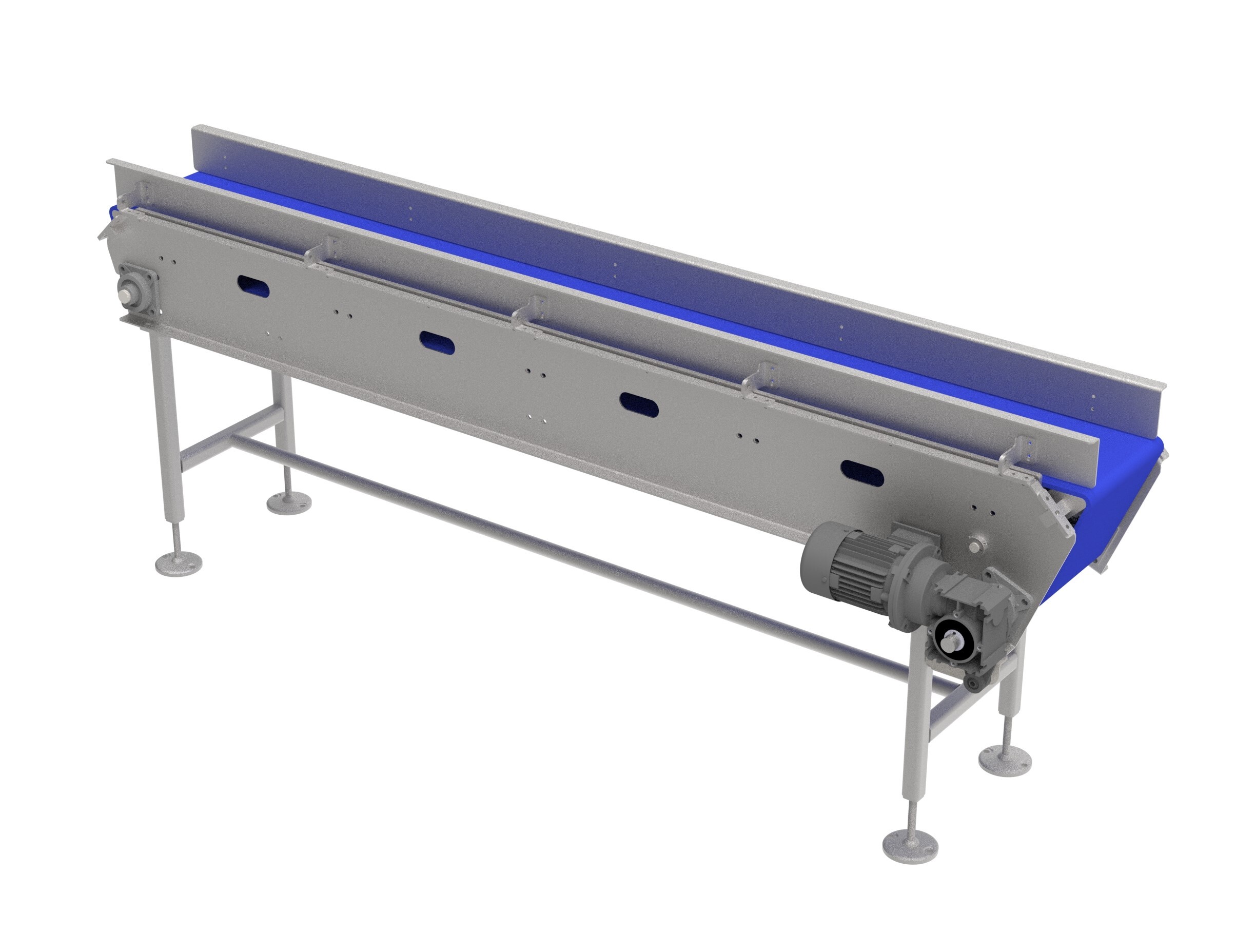

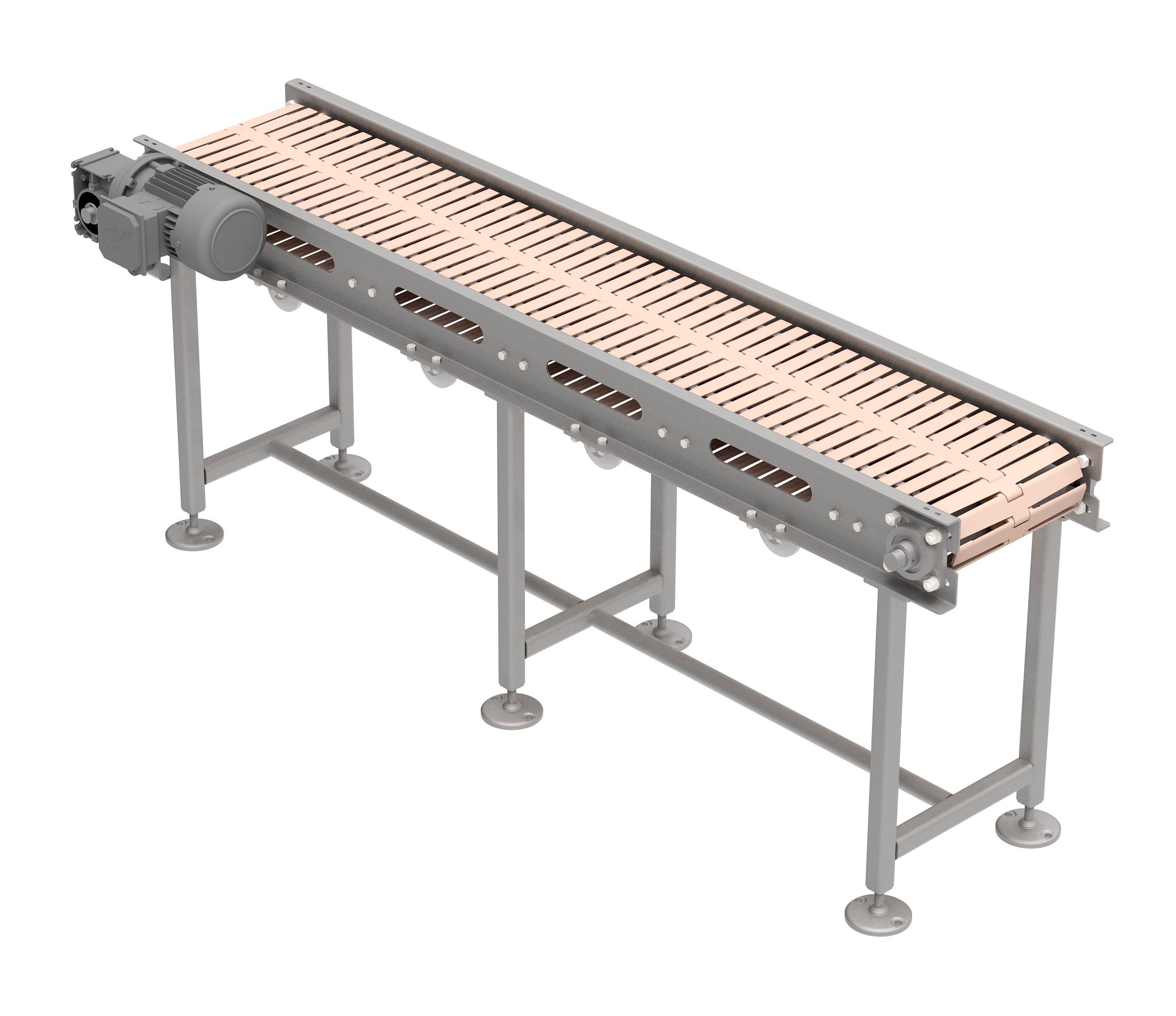

Tabletop conveyors are versatile and efficient tools used in various industries for the seamless movement of materials along a flat surface, which makes it a

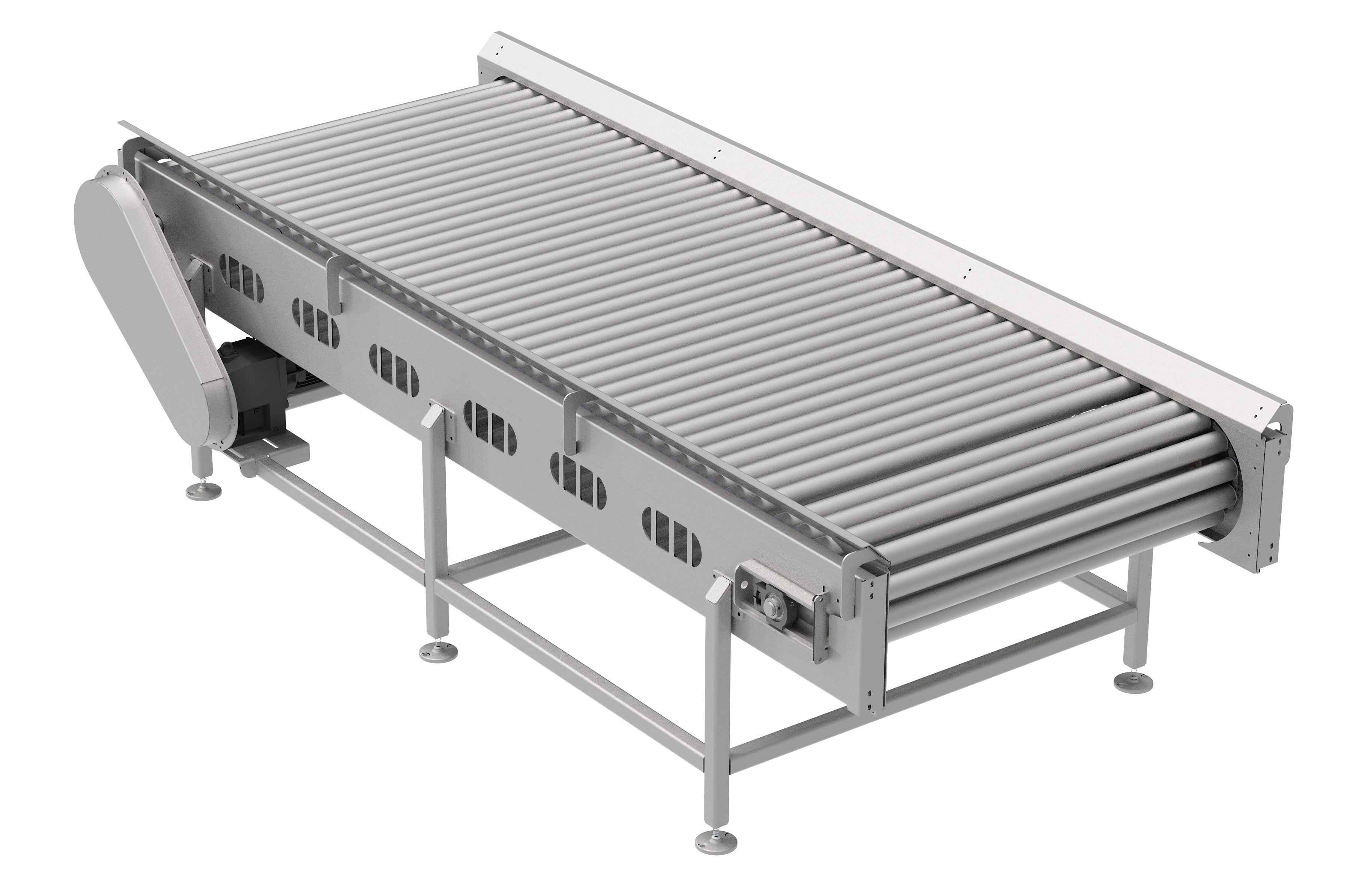

Live roller inspection conveyors are an economical solution and are crucial tools used in various industries and applications, including warehousing, manufacturing, quality control, and product

To operate at peak efficiency, optimizing the transportation of bulk materials is crucial. While manual picking is an option, it wastes valuable time and leaves

Powered roller conveyors are essential components in modern industrial systems, facilitating the efficient and seamless movement of goods and materials. Our conveyors consist of a

GWI’s conveyor systems stand out due to their high level of customization, adherence to sanitation standards, robust and reliable construction, and efficiency. These competitive advantages make GWI a preferred partner for food processors looking for durable, efficient, and tailored conveyor solutions that meet the specific needs of their operations.

Ready to learn more about how GWI’s custom conveyor systems can enhance your food processing operations? Contact us today to discuss your needs and discover how our high-efficiency, sanitary solutions can help you achieve your production goals.

Contact our team of experts to find the best nut processing system for your application. We offer comprehensive support from design to installation and maintenance.

Ghazarian Welding Inc. 2903 E. Annadale Ave. Fresno, CA 93725

Tel: (559) 2331210

Fax: (559) 233-6963