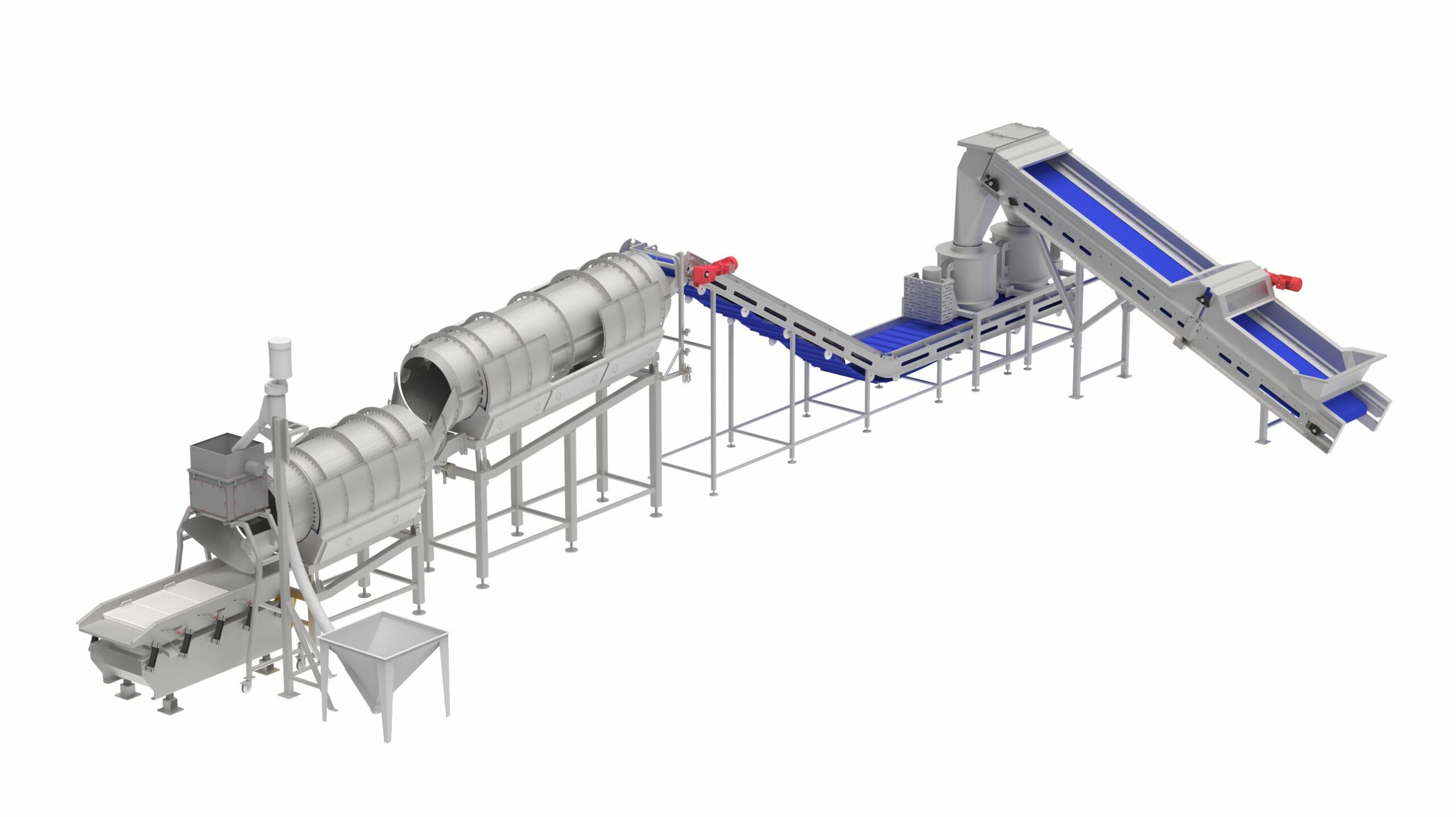

Industrial Flavoring and Coating Systems

GWI’s industrial flavoring and coating systems are engineered to deliver high-efficiency and customizable solutions for food manufacturers. Whether you’re producing snacks, or other food products, including: almonds, cashews, raisins, gummies, mangos, and so much more, our systems ensure consistent flavoring and coating application, maintaining product quality and enhancing consumer appeal.

Our flavoring and coating systems offer significant advantages, especially in terms of customization, sanitation, automation, and energy efficiency. These systems ensure that products maintain high quality and consistency across various food types. GWI’s flavoring and coating systems are competitive in the market. We excel in cost-saving technologies that provide a balanced solution that caters to a wide range of food processing needs.

Process Include:

- Bulk metering in-feed conveyors

- Leveling and layering of product

- singulating any stuck together/clinging materials

- Inspection belt conveyor zones

- Liquid coating tumblers equipped with spray manifolds

- flavor coating tumblers equipped with volumetric ingredient feeding

- Fines removal/excess flavoring collection prior to packaging

Fields marked with an * are required

Contact Us

Ready to optimize your flavoring and coating operations? Contact GWI today to learn more about our customized solutions. Our experts are here to help you find the perfect system for your needs.

Support and Services

- Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

- Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

- Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.