Automated Nut

Processing Systems

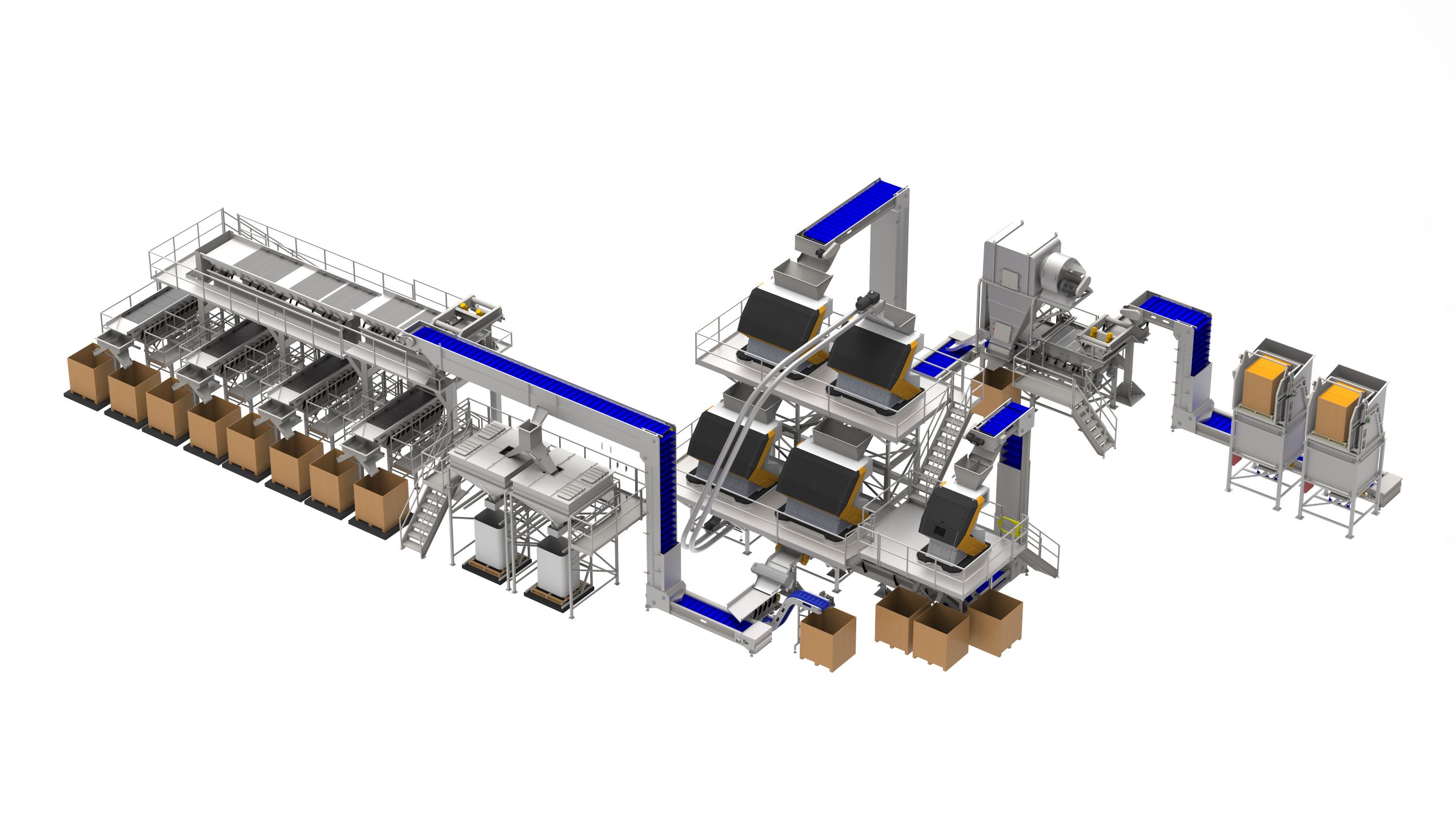

We offer comprehensive nut processing systems designed to handle various stages of nut processing, ensuring high efficiency and quality in production.

Meeting and Exceeding Customer Expectations

GWI’s nut processing systems are designed to provide the highest quality and efficiency in handling various types of nuts. Our systems ensure precise unloading, separating, pre-cleaning, sorting, and packaging, meeting the needs of diverse industrial applications.

Let’s Start Building Your Custom Solution

Have questions about our food processing equipment or services? Reach out to GWI’s expert team today—we’re here to design and deliver solutions tailored to your unique needs!

Fields marked with an * are required

Key Features and Capabilities

Sorting and Grading

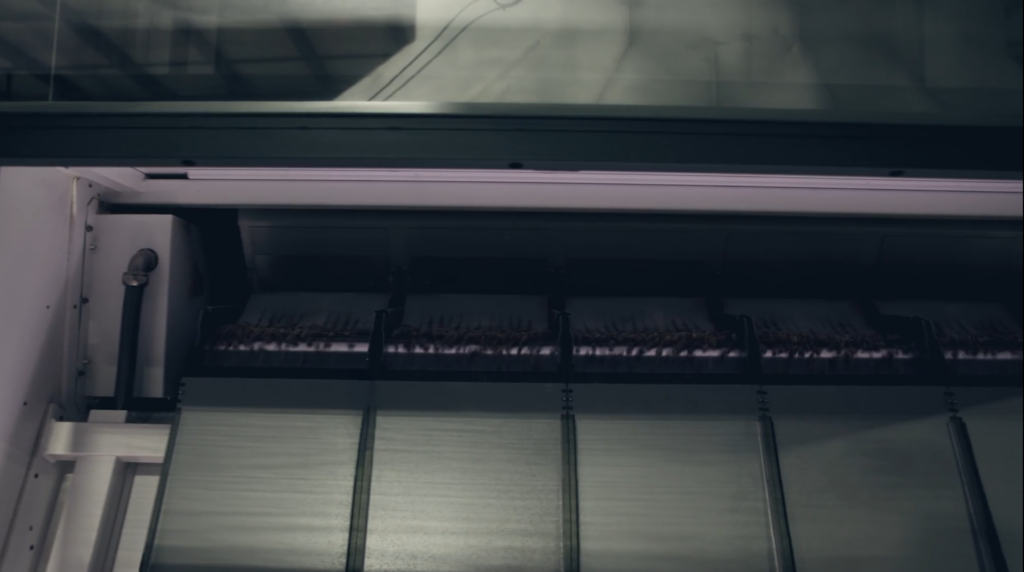

G-Flex Vibratory High-Speed Scalping Systems: These systems separate oversized materials and ensure consistent size grading of nuts.

UVS Air Aspiration Separation Systems: Use air to separate lighter debris from the nuts, enhancing the quality of the final product.

Optical Sorting and X-Ray Integration: Advanced technology for detecting and removing foreign materials and defects from nuts, ensuring high quality and safety.

Sanitary and Safe Operations

Food Safety Standards: Designed to meet stringent food safety standards, GWI’s systems ensure that the nuts are processed in a sanitary environment, which is crucial for maintaining product integrity and consumer safety.

Easy Maintenance: The systems are designed for easy cleaning and maintenance, reducing downtime and ensuring continuous production.

Comprehensive Processing Solutions

All-in-One Systems: GWI’s nut processing systems handle various stages, including unloading, pre-cleaning, sorting, grading, and packaging, providing a comprehensive solution for nut processing facilities.

Versatile Applications: These systems are suitable for processing a wide variety of nuts, including almonds, walnuts, macadamia nuts, pistachios, hazelnuts, Brazil nuts, pecans, peanuts, and cashews.

Economic and Operational Benefits

Cost-Effective: By reducing manual labor and improving processing efficiency, GWI’s systems help lower operational costs and increase profitability.

Reliable Performance: The robust construction and advanced technology of GWI’s systems ensure reliable and consistent performance, reducing the risk of downtime and production delays.

Enhanced Product Quality

Consistent Quality: Advanced sorting and grading technologies ensure that only high-quality nuts reach the market, meeting customer expectations and enhancing brand reputation.

Gentle Handling: The systems are designed to handle nuts gently, minimizing damage and ensuring that the nuts retain their natural quality and appearance.

Types of Nuts Processed

GWI systems can handle a variety of nuts, including:

Almonds Hazelnuts

Walnuts Brazil nuts

Macadamia nuts Pecans

Pistachios Peanuts

Cashews

Why Choose GWI?

Expertise and Experience

These systems are ideal for nut processors looking to improve their production efficiency, product quality, and overall operational effectiveness. With extensive experience in designing and manufacturing nut processing equipment, GWI provides reliable and innovative solutions tailored to your needs.

Customer-Centric Solutions

Our team works closely with clients to deliver customized nut processing solutions that enhance operational efficiency and productivity.

Quality Assurance

very system is rigorously tested to meet the highest standards of quality and performance before leaving our factory.

Support and Services

Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.

Streamline Your Processing Line with Efficient Material Handling Solutions

Enhance your nut processing line with our range of specialized solutions. Discover our precise material handling systems designed to streamline product movement with unmatched efficiency and reliability.