Industrial Mixing Systems for Food Processing

GWI’s mixing systems offer a comprehensive solution engineered for various food processing needs, emphasizing efficiency, sanitation, advanced technology, and customizability. These systems are designed to enhance productivity, improve product quality, and ensure food safety, and reliability, making them an ideal choice for manufacturers looking to enhance their production capabilities including large-scale food manufacturers.

Our solutions are tailored to meet the specific needs of the food industry, ensuring top-quality production capabilities and maintaining high standards of quality and safety.

Benefits

Efficiency and Cost Savings:

- Reduced Labor Costs: Automation reduces the need for manual labor, leading to significant cost savings.

- Energy Efficiency: Designed to minimize energy consumption while maximizing output, and reducing operational costs.

Improved Product Quality:

- Consistent Mixing: Ensures uniform distribution of ingredients, leading to consistent product quality.

- Enhanced Flavor and Texture: Advanced mixing technologies help maintain the natural flavor and texture of food products.

Operational Control:

- Integrated Systems: Seamless integration of various processing stages allows for better control and coordination of operations.

- Data and Analytics: Provides data and analytics to monitor performance, identify inefficiencies, and optimize processing operations.

Customizable Food Mixing Systems for Production Lines

GWI offers customizable food mixing systems to fit your specific operational needs. Whether you need a complete mixing line or individual components, our solutions enhance efficiency and productivity.

PROCESSES INCLUDE:

- Frozen whole and or diced vegetables

- Frozen whole and or diced fruits

- Frozen whole peas (and similar type products)

- Frozen leafy products

PROCESSING COMPONENTS INCLUDE:

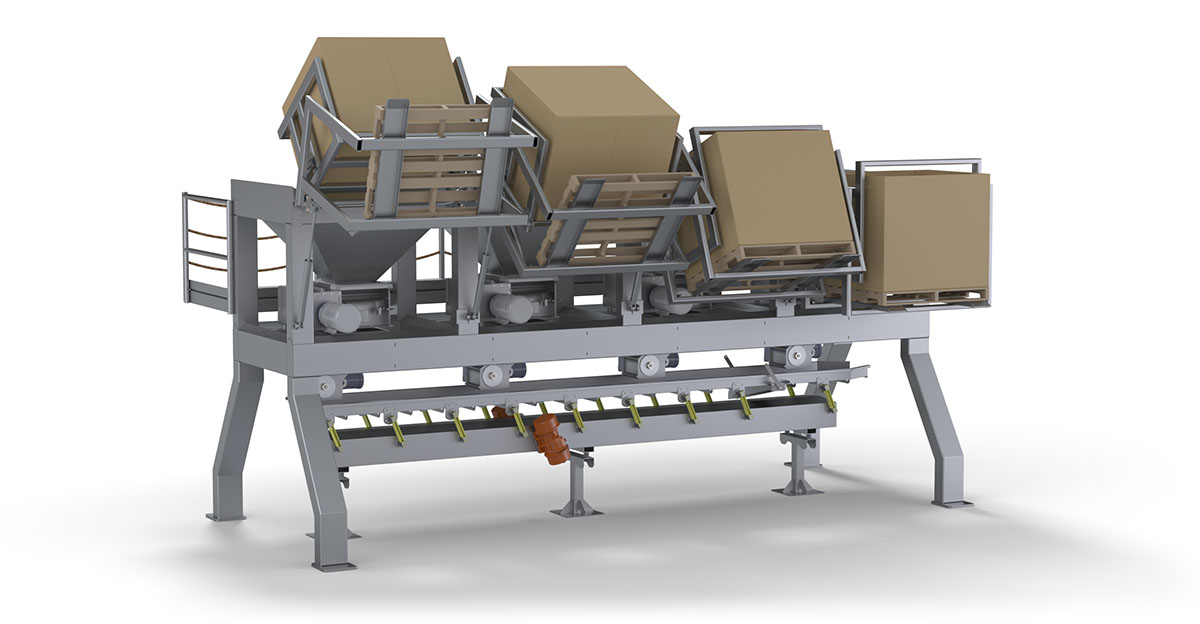

- Two-stage product bin dumping with pallet separation

- Size adjustable frozen product cluster breakers

- Quick change out volumetric metering valves

- GW-FLX vibratory conveyor transfer systems (with fines removal separation if necessary)

Key Features and Capabilities

High Efficiency and Productivity

Automated Systems: GWI mixing systems are fully automated, reducing the need for manual labor and increasing throughput.

High Capacity: Designed to handle large volumes of food products, ensuring efficient processing even during peak production periods.

Advanced Technology Integration

Precision Mixing: Utilizes advanced mixing technologies to ensure thorough and consistent mixing of ingredients.

Control Systems: Equipped with state-of-the-art control systems for monitoring and adjusting mixing parameters in real time.

Customization and Flexibility

Tailored Solutions: GWI offers customizable mixing systems to fit specific operational needs, from small batches to large-scale production lines.

Modular Design: The modular nature of the equipment allows for easy integration with existing systems and scalability for future expansion.

Why Choose GWI?

Expertise and Experience

With extensive experience in designing and manufacturing food processing equipment, GWI provides innovative solutions tailored to your needs.

Customer-Centric Solutions

Our team works closely with clients to deliver customized raisin processing solutions that enhance operational efficiency and productivity.

Quality Assurance

Every system is rigorously tested to meet the highest standards of quality and performance before leaving our factory.

Contact Us

Contact our team of experts to find the best mixing system for your application. We offer comprehensive support from design to installation and maintenance.

Support and Services

Installation and Training

GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

Maintenance and Support

Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

Customization Consultation

Expert consultation to design and customize processing lines tailored to specific requirements.