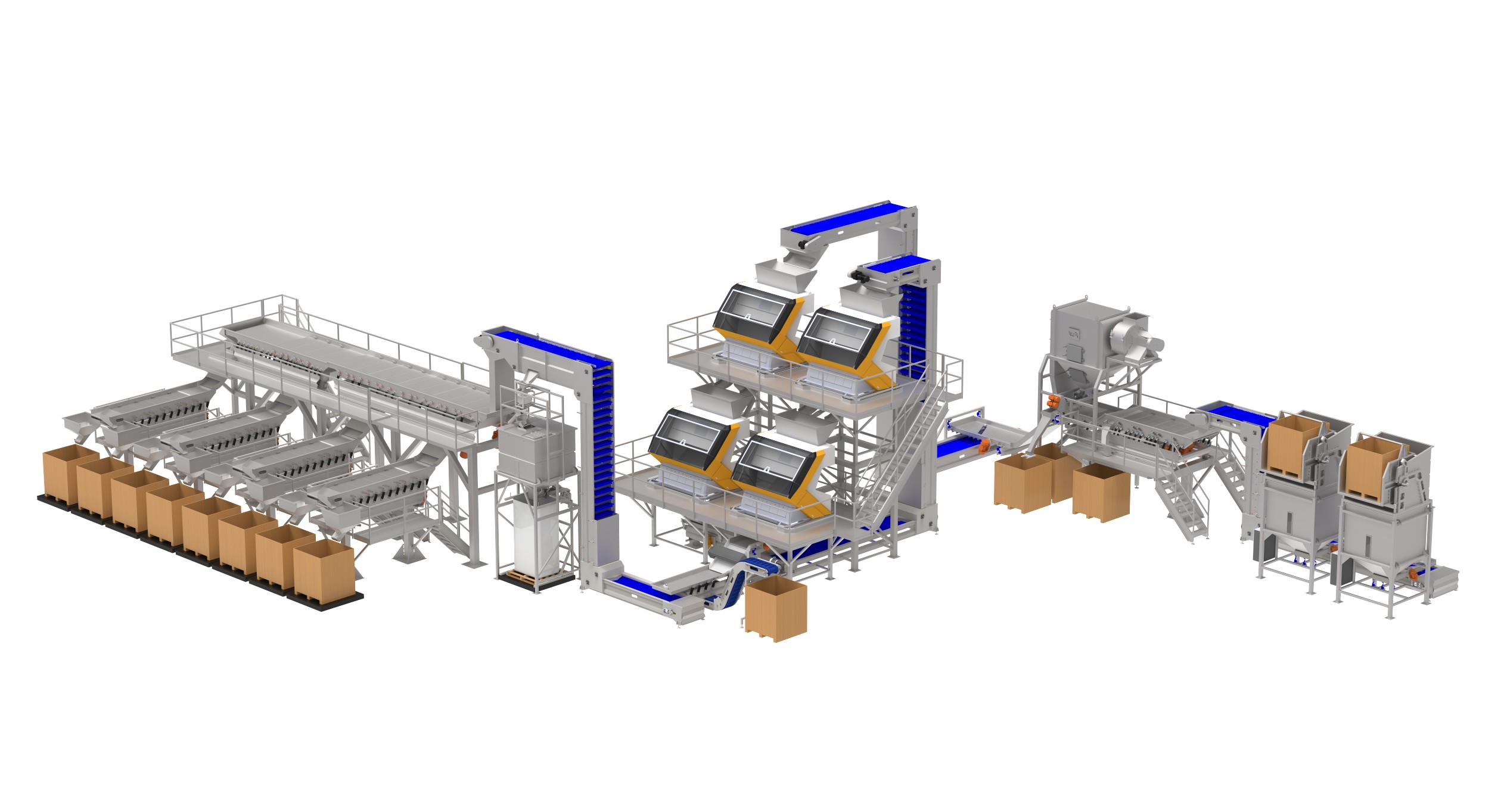

Automated Almond Processing Systems

GWI’s Almond and various tree nut processing systems are designed to provide the highest quality and efficiency across the entire process, including unloading, precleaning, transferring, integrating optical sorting, metal detection, sizing, and bulk packing. We will efficiently and gently remove undesirable materials from good product streams, handling throughputs that range from 5,000 to 60,000 lbs. per hour.

GWI systems are designed to fit seamlessly within your existing facility footprint, we can also design a solution for new facility applications to ensure highly efficient productivity from the start.

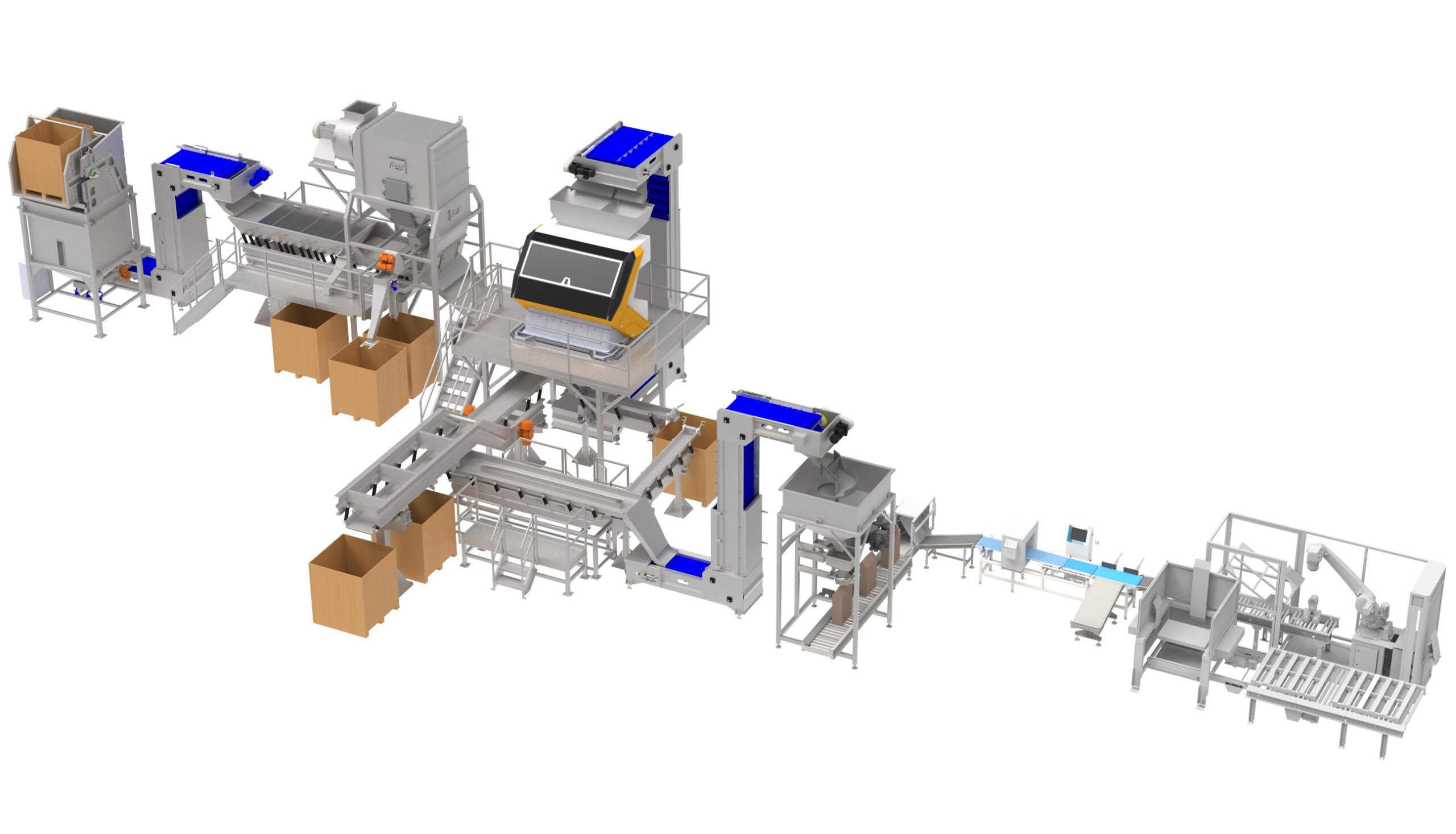

COMPLETE PROCESSING SYSTEMS

Whether you require a complete processing system or specific components for an existing line, GWI will fully design and customize to meet your specific operational needs.

VARIOUS PRODUCT FOCUS:

- Almonds (kernel & in-shell)

- Pistachios (kernel & in-shell)

- Walnuts (kernel & in-shell)

- Macadamias (kernel & in-shell)

- Peanuts (kernel & install)

- Cashews

- Brazil nuts

PROCESSING SPECIFIC EQUIPMENT:

- Bin or bag unload and metering

- G-Flex vibratory high performance scalping & fines removal systems

- UVS density separation systems

- G-Flex high performance size grading systems

- Optical sorting, metal detection, and X-ray integration

- Product transfer elevators and conveyance

- Bulk bin filling, super sack filling, and weighing equipment

Why Choose GWI?

Expertise and Experience

With extensive experience in designing and manufacturing food processing equipment, GWI provides innovative solutions tailored to your needs.

Customer-Centric Solutions

Our team works closely with clients to deliver customized raisin processing solutions that enhance operational efficiency and productivity.

Quality Assurance

Every system is rigorously tested to meet the highest standards of quality and performance before leaving our factory.