CONVEYORS

Explore GWI’s custom conveyor systems with high-efficiency, sanitary, and automated conveyor solutions tailored for the food industry and material handling.

GWI offers a comprehensive range of conveyor systems specifically designed for the food processing industry. Our conveyors are engineered to enhance efficiency, maintain product quality, and meet stringent hygiene standards. Whether you need custom solutions or turnkey systems, GWI provides the expertise and equipment to optimize your production line.

Increasing throughput and capacity requirements, shorter processing times, and rising operational costs are driving production and distribution companies to consider automated conveyor systems. GWI has built a strong reputation for designing, building, installing, including servicing conveyor systems to help companies move their products and materials more efficiently through our industrial conveyor automation solutions. We manufacture a wide variety of options for industrial conveyor systems that are fast and efficient to meet and exceed expectations in transporting loads and materials within an area.

GWI’s industrial conveyor systems are built to handle a variety of materials, from raw ingredients to finished products. Our conveyors are designed to withstand the rigorous demands of food processing environments, ensuring reliable performance day after day.

Key Features:

Integrity

We believe in doing the right thing, every time.

Quality

Our products are built to last, ensuring long-term reliability and performance.

Customer Focus

We are dedicated to understanding and meeting the unique needs of each client.

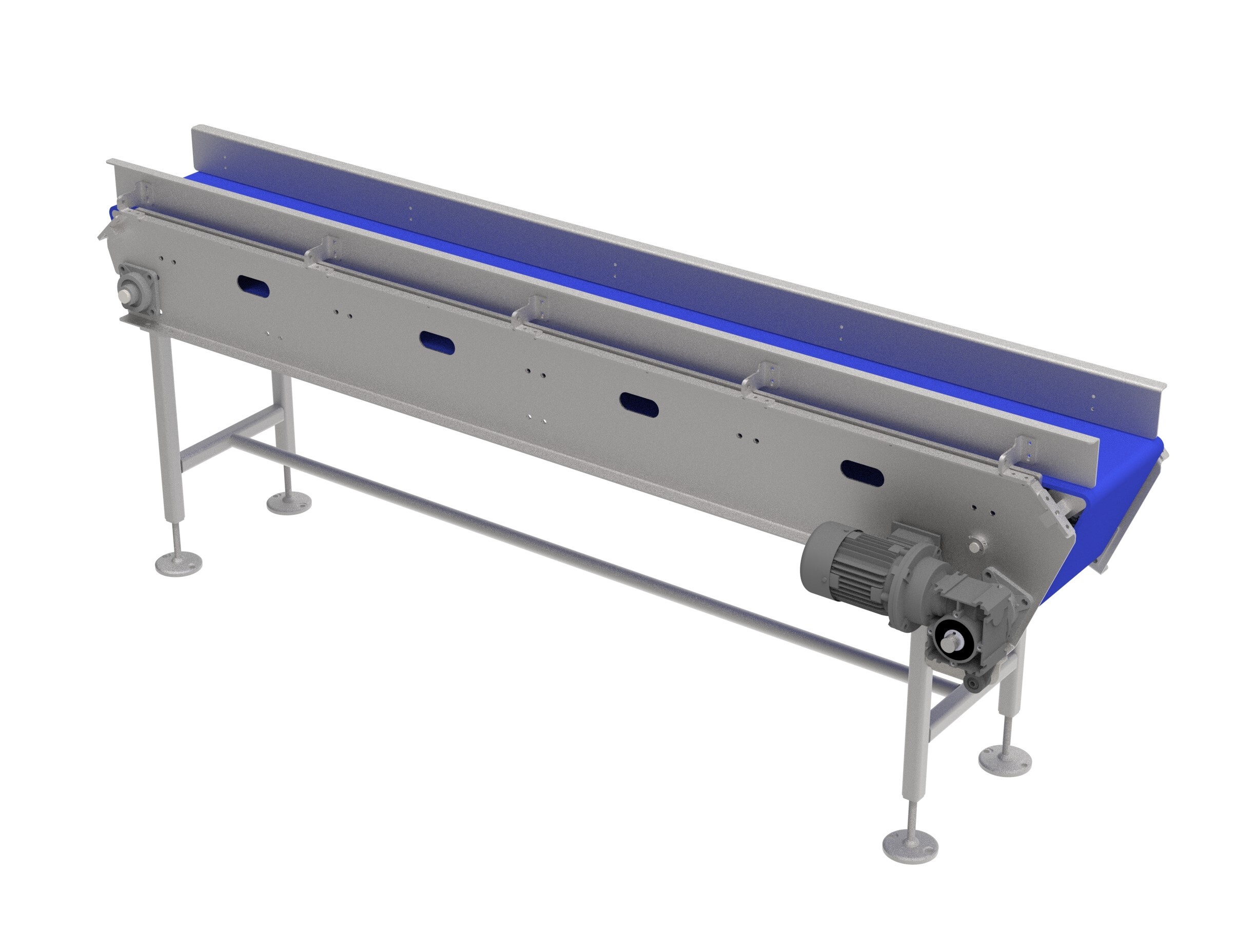

INCLINE PROFILE

GWI’s custom incline profile conveyors are designed to meet the specific needs of food processing and bulk material handling industries. Our conveyors ensure the efficient transportation of products up inclined surfaces, improving production flow and productivity. Whether you need automated, high-efficiency, or sanitary incline conveyors, GWI has the solution to keep your food processing plant running smoothly.

BULK METERING

Our advanced bulk metering systems for moving materials offer precision and durability, ensuring seamless flow management across industries. Designed for high-accuracy bulk material handling, our metering solutions support large-scale operations, streamlining logistics with industrial-strength performance. Whether you need custom bulk material flow meters or heavy-duty metering equipment, our systems meet the demands of intensive material transport applications.

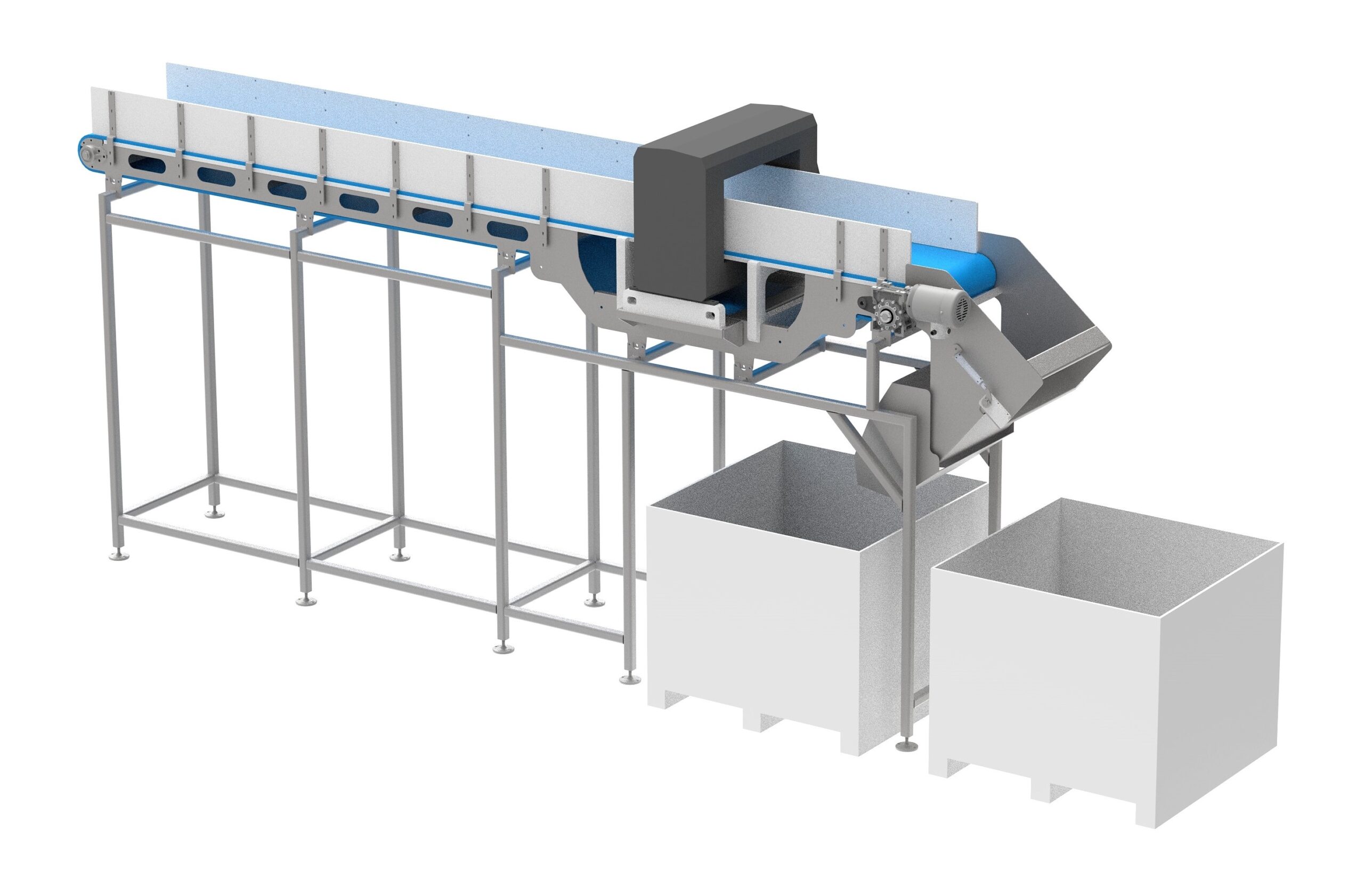

METAL DETECTION CONVEYORS

Looking to buy high-sensitivity metal detecting conveyors for enhanced quality control in food processing or material handling industries? Our industrial metal detecting conveyors for sale offer customizable solutions, designed to meet stringent safety compliance standards and prevent contamination. Equipped with advanced features, these conveyors support precision in detecting ferrous and non-ferrous metals in bulk or packaged products.

ACCUMULATION TURNTABLES

Discover our automated accumulation turntables for production lines, designed to increase production efficiency while reducing labor costs. Our adjustable height rotary accumulation tables for warehouses

NOSE-BAR BELT CONVEYORS

Discover our high-performance nose transition belts for material handling systems, designed to enhance efficiency and reduce downtime in your operations. Our adjustable nose transition belts

BUCKET DISTRIBUTION CONVEYOR

Explore our high-capacity bucket distribution conveyors for manufacturing, engineered to enhance efficiency in material handling. Our automated bucket distribution conveyors for warehouses provide seamless integration

V-TROUGH CONVEYOR

GWI’s V-trough conveyors are engineered for efficient bulk material handling across food processing and industrial sectors, ensuring smooth, automated material flow with minimal maintenance. These

SCREW CONVEYORS

Our screw conveyors or auger conveyors are mechanical devices used for transporting bulk materials from one location to another. They consist of a rotating helical

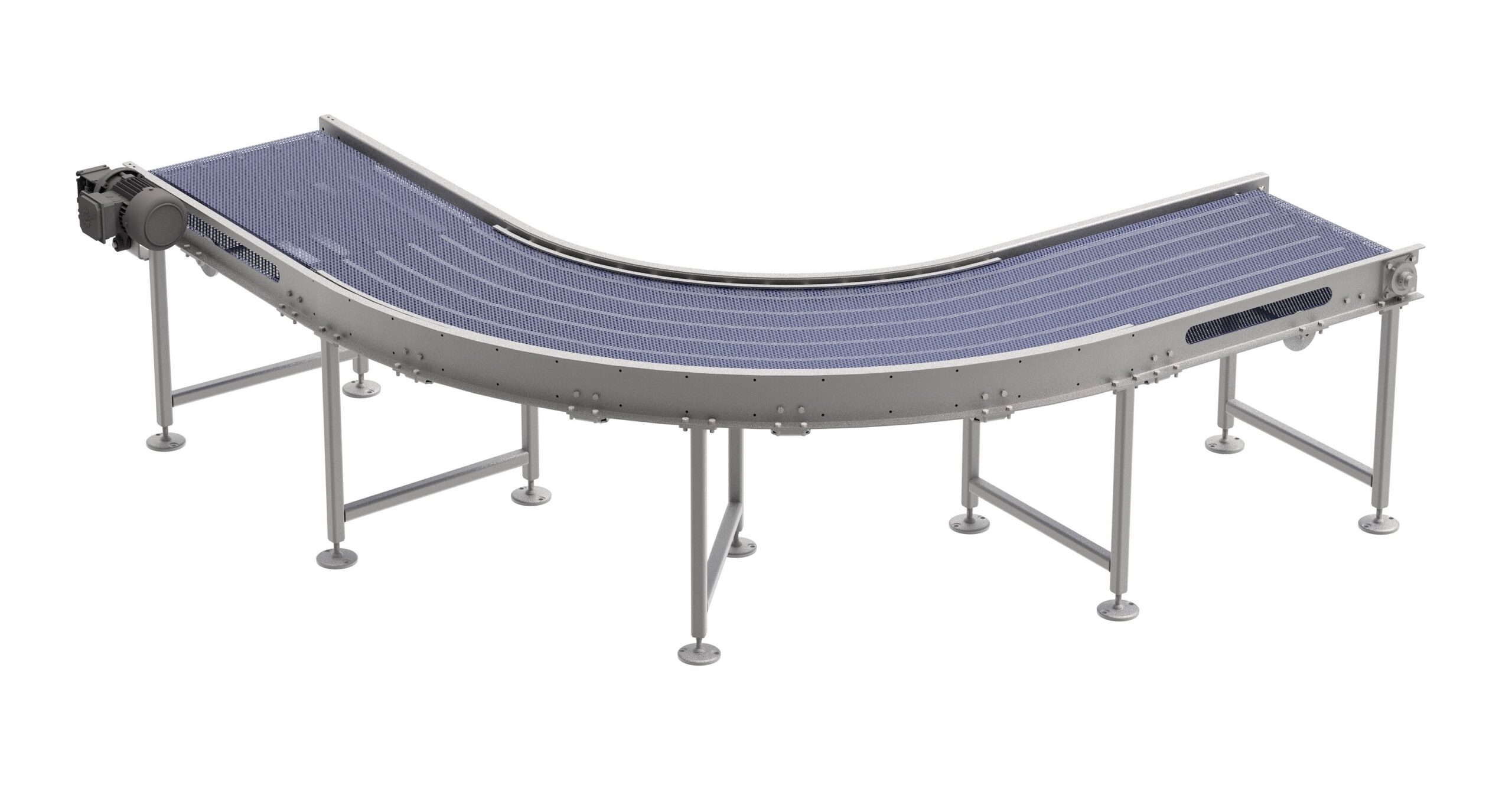

TABLE TOP CONVEYORS

Tabletop conveyors are versatile and efficient tools used in various industries for the seamless movement of materials along a flat surface, which makes it a

LIVE ROLLER INSPECTION

Live roller inspection conveyors are an economical solution and are crucial tools used in various industries and applications, including warehousing, manufacturing, quality control, and product

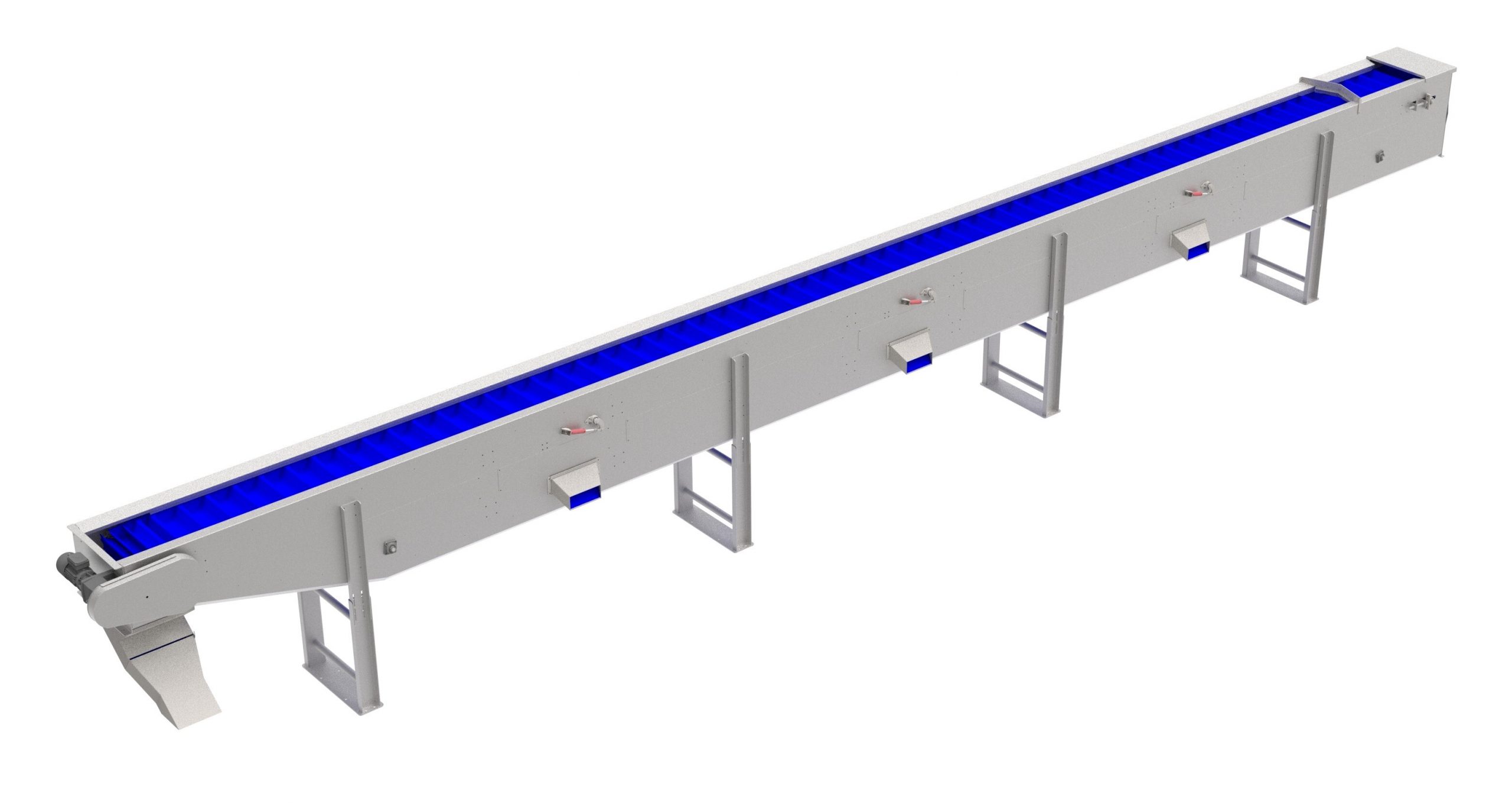

VARIOUS PROFILE BELT CONVEYORS

To operate at peak efficiency, optimizing the transportation of bulk materials is crucial. While manual picking is an option, it wastes valuable time and leaves

POWERED ROLLER CONVEYORS

Powered roller conveyors are essential components in modern industrial systems, facilitating the efficient and seamless movement of goods and materials. Our conveyors consist of a

ACCELERATION CONVEYORS

GWI’s Acceleration Conveyor smoothly increases product speed to create consistent spacing and reliable feeding into higher-speed food processing and packaging equipment.

Competitive Advantages

GWI’s conveyor systems stand out due to their high level of customization, adherence to sanitation standards, robust and reliable construction, and efficiency. These competitive advantages make GWI a preferred partner for food processors looking for durable, efficient, and tailored conveyor solutions that meet the specific needs of their operations.

1. Tailored Design: GWI excels in providing fully customizable conveyor systems that can be designed to meet the specific needs of each customer. Whether a facility requires unique configurations for handling delicate products or specialized equipment for heavy-duty operations, GWI offers flexible solutions that fit seamlessly into existing production lines.

2. Integration Capabilities: GWI’s conveyors can be easily integrated with other processing equipment, enhancing the efficiency and effectiveness of the entire production process. This adaptability makes them suitable for a wide range of industries and applications.

1. Food-Grade Materials: GWI uses food-grade materials in the construction of their conveyor systems, ensuring compliance with the strict hygiene standards required in the food processing industry. The design focuses on preventing contamination and facilitating easy cleaning, which is essential for maintaining product safety.

2. Ease of Cleaning: The conveyors are designed with smooth surfaces and minimal crevices, making them easy to clean and maintain. This reduces downtime associated with sanitation and helps maintain continuous production flow.

1. Robust Construction: GWI’s conveyor systems are built with durability in mind, using high-quality materials that withstand the rigorous demands of industrial food processing. This ensures long-term reliability and reduces the need for frequent maintenance or replacements, leading to lower operational costs.

2. Consistent Performance: The conveyors are engineered to deliver consistent performance even under heavy use, ensuring that production lines operate efficiently without unexpected interruptions.

1. Energy Efficiency: GWI designs its conveyors to be energy-efficient, which not only reduces the environmental impact but also lowers operating costs. This focus on efficiency helps food processors optimize their operations while maintaining high productivity.

2. Automation Capabilities: The ability to integrate automation into GWI’s conveyor systems further enhances efficiency by reducing manual intervention and allowing for real-time monitoring and adjustments.

1. Turnkey Solutions: GWI offers turnkey conveyor solutions that are ready to operate from the moment they are installed. This includes full assembly, testing, and expert installation, ensuring that clients can quickly integrate these systems into their operations.

2. Ongoing Maintenance and Support: GWI provides comprehensive support services, including maintenance and repair, to ensure that conveyor systems continue to perform optimally over time. This commitment to customer service strengthens the long-term value of their equipment.

Why Choose GWI?

Expertise and Experience

With extensive experience in designing and manufacturing food processing equipment, GWI provides innovative solutions tailored to your needs.

Customer-Centric Solutions

Our team works closely with clients to deliver customized raisin processing solutions that enhance operational efficiency and productivity.

Quality Assurance

Every system is rigorously tested to meet the highest standards of quality and performance before leaving our factory.